|

||

|

|

||

|

Page Title:

Dredge Process Data to Monitor Dredge Performance |

||

| |||||||||||||||

|

|

administrator can use this model in conjunction with the actual monitoring data to insure that the

dredge is meeting minimal production requirements.

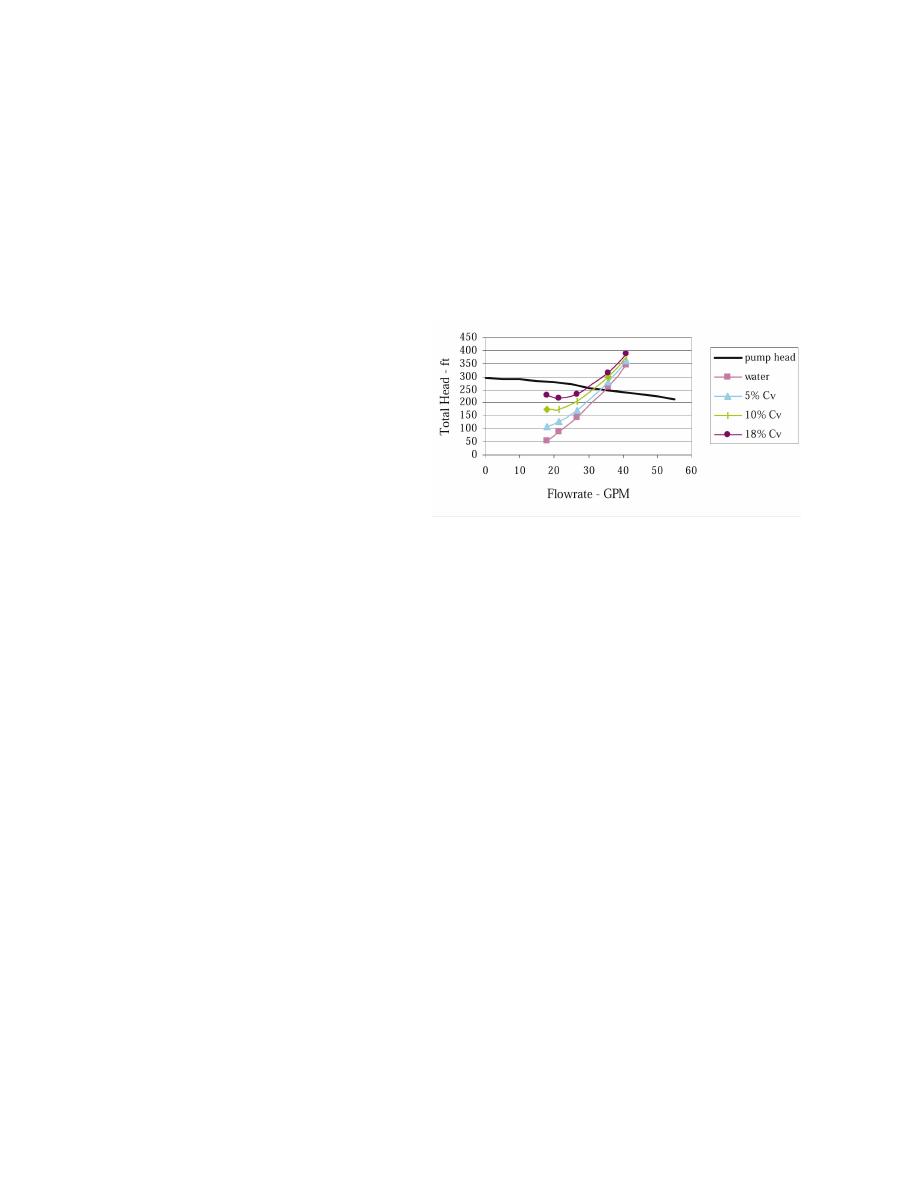

Another component essential to the pre-dredge analysis is the dredge pump characteristic curve,

which details the relationship between pump discharge head, discharge, efficiency, horsepower, and

pump speed. Data generated from the theoretical dredge model can be used in conjunction with the

pump curve to determine the approximate pump operating point during the project. This is essential

to insuring that the pump operates above the minimum flow rate for settling of solids in the pipeline

and that horsepower limitations are not a controlling factor.

Figure 1 is an example of the pump curve

for a 0.68- by 0.68-m- (27- by 27-in.-)

dredge pump with a 2,134-m- (7,000-ft-)

long discharge line at the maximum pump

speed, 575 rpm. The maximum pump

power available is 2,237 kW (3,000 hp).

The system head requirement curves gen-

erated from a dredge performance model

are plotted on the pump curve. These

curves represent water in the pipe, 5 per-

cent by volume solids slurry, 10 percent

by volume solids slurry, and 18 percent by

volume solids slurry. The sand size is

0.16 mm (0.0006 in.), with a critical velocity of deposition in the 0.68-m (27.0-in.) pipe of about

3.66 m/sec (12.0 ft/sec) or 81,052 L/min (21,414 gpm).

The pump will operate at the intersection of the system curves and the pump curve. The 18 percent

solids system curve intersects the pump curve at a head of about 255 ft of water and a discharge of

approximately 113,550 L/min (30,000 gpm) (5.12 m/sec (16.8 ft/sec) flow velocity in the pipeline).

This dredge is capable of pumping the maximum concentration of solids (18 percent) at a velocity

above the minimum velocity required to prevent deposition in the pipeline. Dredge production is

approximately 1,618 m3/hr (2,115 yd3/hr) with 2,152 kW (2,886 hp) required.

In summary, dredge performance can be estimated using the dredge performance model in

conjunction with the pump characteristics curve. The model provides estimated values of slurry

density (solids concentration) and dredge production during each phase of the dredging cycle. These

values can be compared to the real-time slurry density and velocity data acquired from the production

meter on the dredge.

Dredge Process Data to Monitor Dredge Performance. A number of monitoring systems

can be used on a pipeline dredge to assist in maintaining dredge production (Pankow 1989). The

most common instrumentation for monitoring solids transport are the velocity meter and slurry

density gauge. The velocity of the dredged slurry in the pipeline can be measured with a variety of

types of flow meters. The slurry velocity data alone is not descriptive of the efficiency of the dredge

plant, but when evaluated in conjunction with the slurry density measurement, a relative measure

of dredge production rate can be made.by

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |