|

||

|

|

||

|

Page Title:

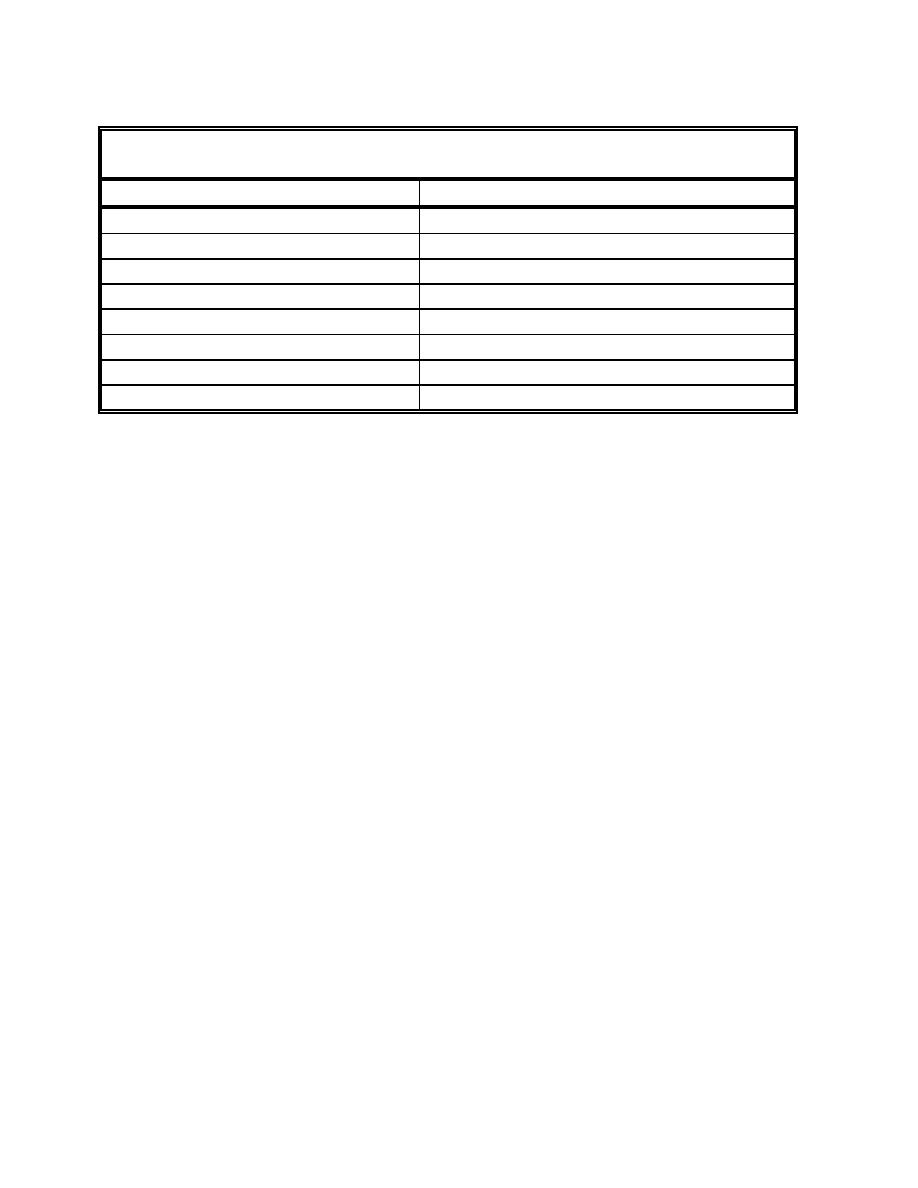

Table 1. Data Collected for Hopper and Pipeline Dredge SI Systems |

||

| |||||||||||||||

|

|

ERDC TN-DOER-I6

March 2001

Table 1

Data Collected for Hopper and Pipeline Dredge SI Systems

Hopper Dredge

Pipeline Dredge

Horizontal position

Cutterhead horizontal position and depth

Hopper status (open/closed)

Slurry velocity and density

Tide level

Tide level or river stage

Ship speed and heading

Dredge heading

Material recovery and min. pump effort

N/A

Draft, displacement

N/A

Hopper ullage and volume

N/A

Draghead depth

N/A

Both hopper and pipeline dredge SI systems have been field proven through demonstration

projects. Recently, the SI system was implemented on two hopper dredges: Bean Stuyvesant's

Stuyvesant in May 2000, and the B+B Dredging Company Columbus (later renamed the

Columbia) in January 1998. Also in 1999, pipeline SI system implementation was tested on the

Corps dredge, the William A. Thompson.

IMPLEMENTATION PROCESS: The SI implementation process consists of developing and

defining the interactive Corps and dredging contractor relationship so that management decisions

can be obtained from a common basis of factual information. The SI System implementation

process is one of continuous improvement and is described in several major steps.

Step 1. Corps development of SI contract specifications and submittal of those specifications

to the contractor (via the contracting process)

submittal of the DPIP to the Corps

Step 3. Corps approval of the DPIP

Step 4. Contractor provides an operational SI system

Step 5. Corps installs SI software

Step 6. Corps inspects SI system

Step 7. Continued quality assurance testing and contractor quality control throughout

dredging operations (Corps and contractor)

Step 8. Incorporate lessons learned and technology improvements into the contract

specifications and repeat Steps 1-7 for subsequent projects

SI Contract Specifications. The SI contract specifications define and describe the Corps and

dredging contractor relationship with regard to SI system equipment, data collection, data quality

control, and data quality assurance. A Process Action Team (PAT) composed of dredging

contractors and the Corps developed an SI contract specification guide.

Dredging

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |