|

||

|

|

||

|

Page Title:

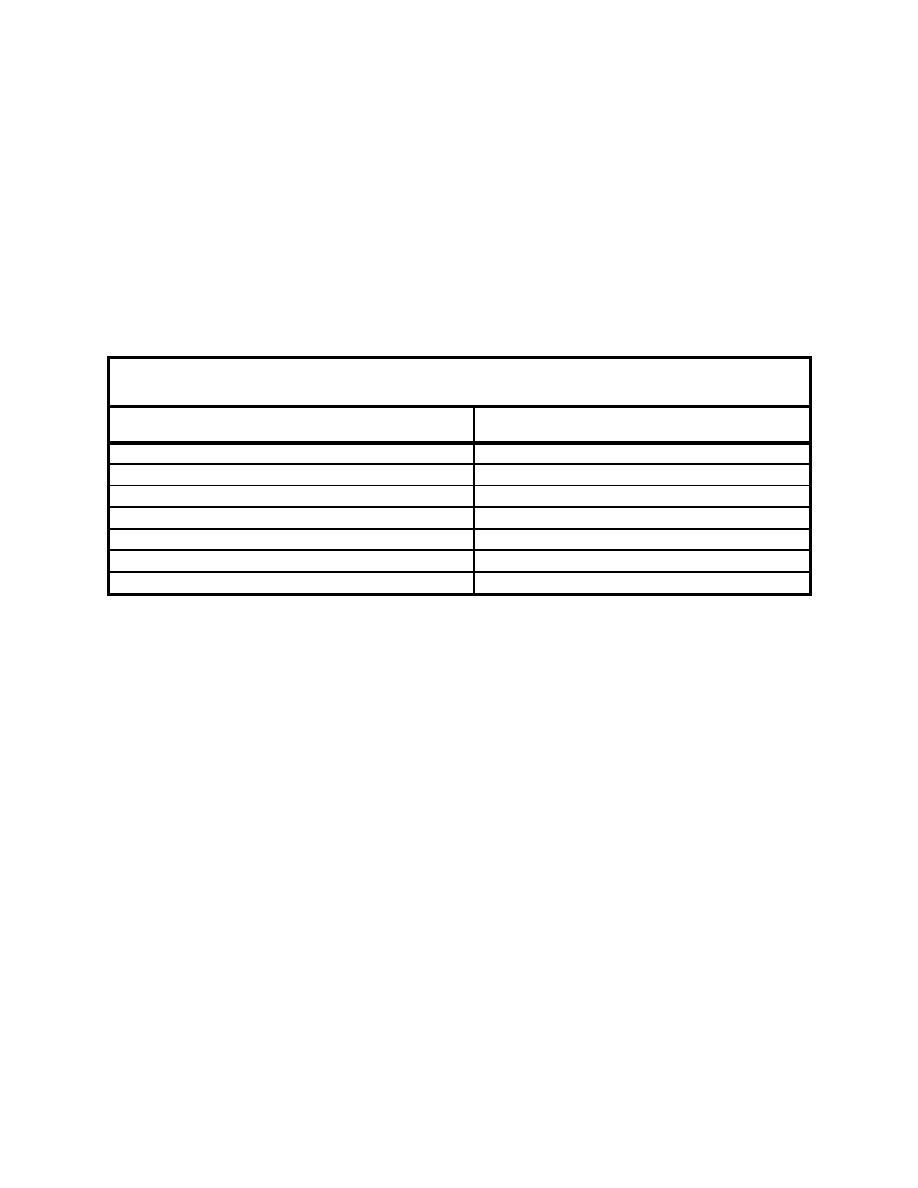

Table 2. Hydraulic Conductivities of Various Soil Liners |

||

| |||||||||||||||

|

|

ERDC TN-DOER-R6

December 2004

employed while maintaining sufficient control of leachate. In most situations, uncontaminated fine-

grained, low-permeability material is readily available for use in liner systems. Initial excavation for

dikes or for site preparation will typically remove topsoil and possibly a layer of foundation soil. The

bottom of the excavation may then be compacted to an optimal density through use of a sheeps-foot

roller, vibratory roller, or other type of compaction equipment. If additional soil liner thickness is

required, lifts of additional soil approximately 6 in. in depth should be applied, ensuring that each lift is

well connected to previous and subsequent lifts through the use of sheeps-foot rollers. It is critical that

optimum water content be maintained throughout the liner construction operation. Further discussion of

compactive effort and moisture content requirements for optimization of hydraulic conductivity and shear

strength of soil liner systems are provided in EM 1110-1-502 (USACE 1994), EPA/625/6-88/018

(USEPA 1988a), EPA/600/2-88/052 (USEPA 1988b), 57 FR 3462 (USEPA 1992a), and in later sections

of this document.

Table 2

Hydraulic Conductivities of Various Soil Liners

Unified Soil Classification System (USCS) or Liner

Hydraulic Conductivity (cm/s)

Classification

10-9 to 10-6 (Fetter 2001)

Clay

10-7 (Schroeder et al. 1994)

Barrier Soil

6.8x10-7 (Schroeder et al. 1994)

CH (Inorganic Clay of high plasticity)

7.8x10-7 (Schroeder et al. 1994)

SC (Sand Clay)

10-9 to 10-7 (Giroud et al. 1997)

Compacted Soil (see ref. for site specifics)

3x10-9 (Schroeder et al. 1994)

Bentonite Mat (0.6 cm)

10-10 to 10-9 (Giroud et al. 1997)

Colloidal Clay

Clean Dredged Material. An inexpensive and efficient liner material that should not be overlooked in

the design of CDFs is clean dredged material. When allowed to settle and condense, fine-grained material

dredged from rivers and harbors can reach permeabilities as low as 10-7 to 10-10 cm/s (Giroud et al. 1997,

Schroeder et al. 1994). By most standards, this range of liner permeability is acceptable for service as

hydraulic barriers.

With this option, areas of the channel that contain uncontaminated material are dredged first, and the

material is pumped into the CDF. Following dewatering and consolidation, clean fine-grained dredged

material can form a low-permeability layer. If application of fine-grained dredged material occurs after

placement and compaction of a low-permeability subsoil liner, clean fine-grained dredged material will

add to the total effective thickness of the liner system. Besides possessing an enhanced hydraulic barrier

following consolidation, the dredged material often contains appreciable amounts of organic carbon,

which increases the sorption capacity of the liner system, further retarding the transport of hydrophobic

organic contaminants through the liner system. The Primary Consolidation, Secondary Compression, and

Desiccation of Dredged Fill (PSDDF) computer program (Stark 1996) provides a means to quantify

consolidation and settlement of dredged material and its impact on hydraulic conductivity.

Modified Soils/Dredged Material. It may be necessary to site CDFs where soils and dredged material

with high hydraulic conductivity (e.g., silts or sand) are ubiquitous as the natural material. Their use as

liner components is limited by their hydraulic conductivity. Examples of other materials that possess

high hydraulic conductivities are provided in Table 3. The preferred hydraulic conductivity for barrier

systems is 10-5 to 10-8 cm/s; thus, either the native soil must be modified to reduce its hydraulic

conductivity to acceptable levels, a borrow (offsite) material of lower hydraulic conductivity must be

brought in and installed, or more sophisticated liner systems (e.g., geomembranes) must be employed.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |