|

||

|

|

||

|

Page Title:

Table 5. Comparison of CCL with GCL (after Daniel and Wu (1993)) |

||

| |||||||||||||||

|

|

ERDC TN-DOER-R6

December 2004

Geosynthetic clay liners. Geosynthetic clay liners

(GCLs) consist of a clay layer between two layers of a Table 4

synthetic material, with the intention of preventing Bentonite Properties

leachate from infiltrating the clay and passing through Property

Value

holes and tears in the synthetic liner. GCLs use a Liquid limit

500-600%

prefabricated multiple layer system to reduce the Plastic limit

30-60%

<10-9 cm/sec

permeability of the liner and to minimize the cost and the Hydraulic conductivity

thickness of the liner. Table 4 lists the properties of pH

9

bentonite clay, which is used as the center layer for many Moisture content (field)

24%

GCLs. Bentonite clay consists of platelets that are Moisture content (processed)

8%

ionically charged and thus attract polar molecules such as water (Gundle Lining Systems, Inc. 1993). The

polar water molecules wedge themselves between the molecules of the clay and cause swelling to occur.

This swelling effect reduces the permeability of the clay by nearly eliminating any flow paths between the

platelets. When the clay is combined with the geomembrane layers, the resulting liner efficiently blocks

the migration of an aqueous solution that contains contaminants. The layers of geomembranes between

which the clay is sandwiched prevent desiccation as described in the previous section on compacted clay

liners.

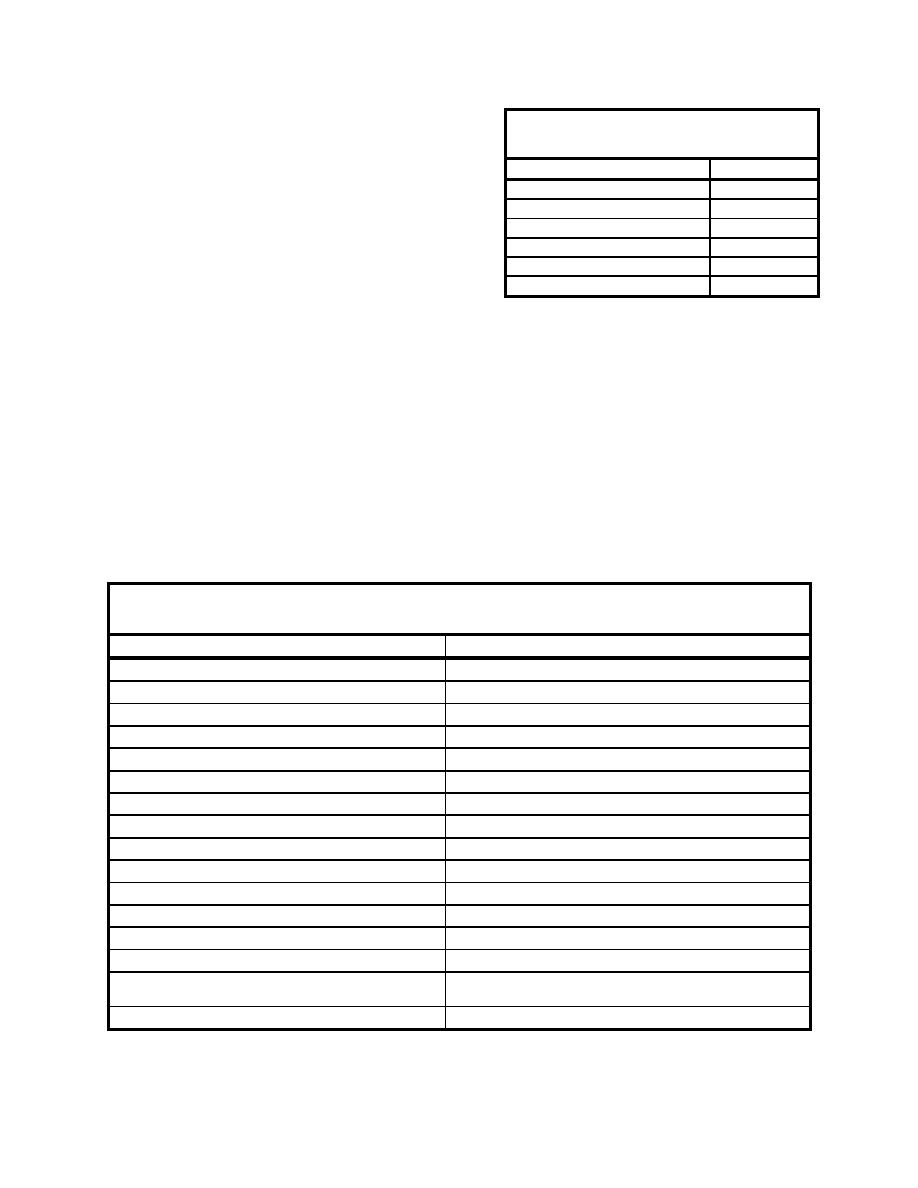

Daniel and Wu (1993) compared the qualities of GCLs to those of compacted clay liners (CCLs) (Table

5) for municipal landfills. Their comparison leads one to believe that GCLs are a more viable option than

CCLs, except for very short storage periods (e.g., less than five years) (Qian 1995). With the large areal

extent of CDFs, however, the GCL may prove to be a significantly more expensive option compared to a

CCL, which may be locally available and cost many times less to employ.

Table 5

Comparison of CCL with GCL (after Daniel and Wu (1993))

Compacted Clay Liner

Geosynthetic Clay Liner

Thick (0.6 ~ 1.5 m)

Thin (<10 mm)

Field constructed

Manufactured

Hard to build correctly

Easy to build (unroll and place)

Impossible to puncture

Possible to damage and puncture

Constructed with heavy equipment

Light construction equipment required

Often requires test pad at each site

Repeated field testing not needed

Site-specific data on soils needed

Manufactured product; data available

Large leachate-attenuation capacity

Small leachate-attenuation capacity

Large thickness; takes up space

Little space is wasted

Cost is highly variable

More predictable cost

Soil has low tensile strength

Higher tensile strength

Can desiccate and crack

Cannot crack until wetted

Difficult to repair

Not difficult to repair

Vulnerable to freeze-thaw damage

Less susceptible to freeze-thaw damage

Performance depends highly on quality of

Hydraulic properties are less sensitive to construction

construction

variabilities

Slow construction

Much faster construction

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |