|

||

|

|

||

|

Page Title:

INNOVATION WITHIN THE CORPS (cont.) |

||

| |||||||||||||||

|

|

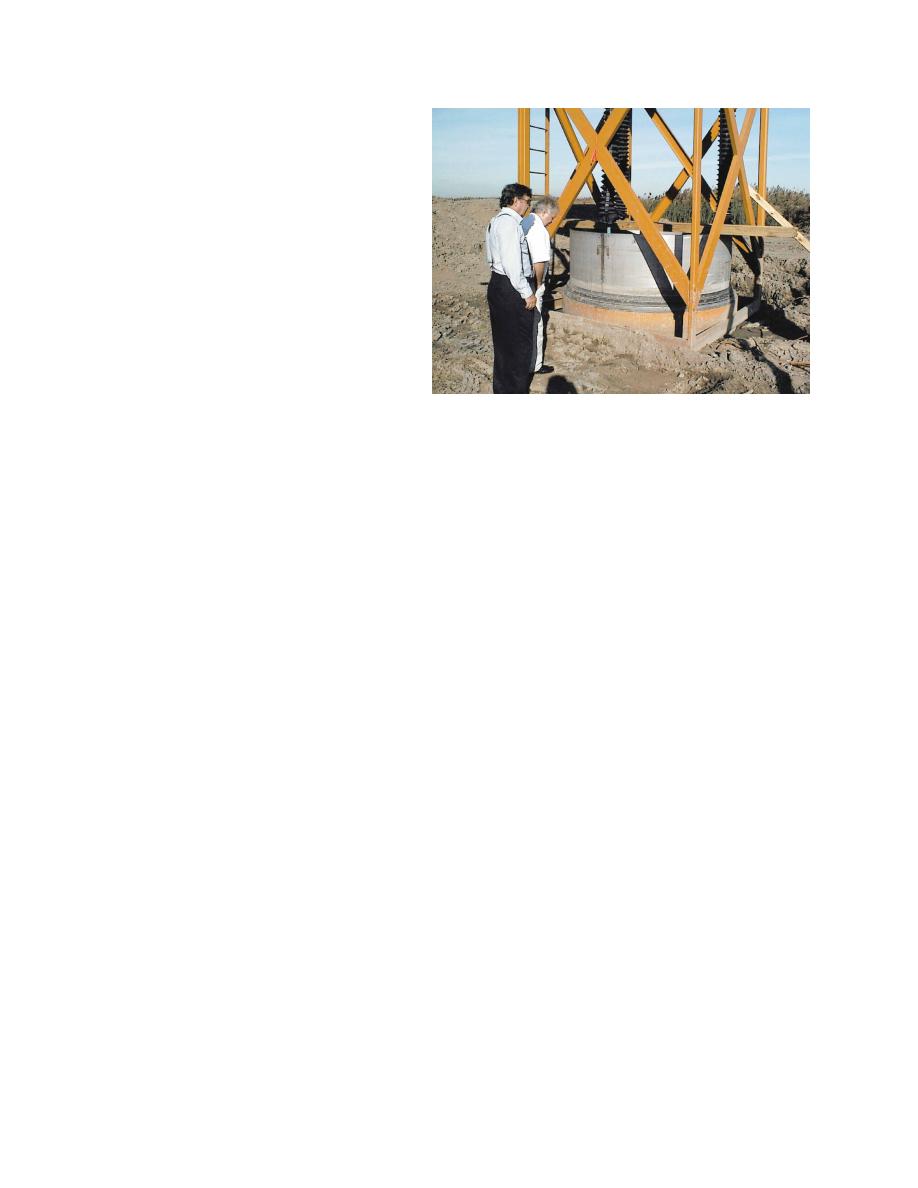

below the water surface, the decant water

flows over the weir crest into the interior

sections, exits through the discharge pipe

in the lower section, and returns to the

surface water course outside the CDF.

This weir has numerous advantages. The

principal advantage is that it provides an

infinite elevation adjustment of the weir

crest (within the weir design height) and

discharge velocities at the touch of a but-

ton. The crest of the telescoping weir can

be lowered easily to the bottom of the

desiccation cracks in the dredged material.

This flexibility also provides efficient con-

trol of surface runoff, enhancement of the

desiccation and the drying processes, and

some measure of mosquito control. The

telescoping weir reduces labor requirements and costs through the elimination of weir board

handling, weir board replacement, weir maintenance, and possible weir failure. The weir promotes

safer field operations, which is another significant advantage. It can be equipped with a variety of

sensors to measure effluent turbidity, temperature, pH, and oxygen levels. Most significantly, this

innovative technology offers a new standard in an area of dredging management that has been very

difficult to improve upon for many years.

To date, three full-size telescoping weirs have been installed at the Craney Island CDF in Norfolk,

VA. The first prototype telescoping weir was installed in April 1996, the second was installed in

June 1998, and the third was installed in April 1999. The first weir performed so well, along with

two conventional weirs, that the Norfolk District was able to accommodate a record annual

placement of 6 million cubic yards of maintenance dredged material. Efficient performance of the

telescoping weir eliminated the usual temporary shutdowns of two very large dredging projects.

The first two weirs are operational and have required virtually no maintenance to date.

Presently, the Norfolk District is assisting the U.S. Army Engineer District, Mobile, with design

and installation of their first telescoping weir. This work should be completed in early 2000. The

innovative device has high potential to be used throughout the Corps and other industrial facilities

worldwide. Patents for the telescoping weir are pending with the U.S. Patent Agency and foreign

countries.

The Innovative Technology Focus Area under DOER is partnering with the Norfolk District to

transfer the technology to various Corps users, including the Mobile District. This partnership serves

to promote the use of and will aid in the technology transfer to other Corps Districts. In addition to

the technical assistance provided under DOER, the U.S. Army Engineer Research and Development

Center, Environmental Laboratory, has signed an agreement with the Norfolk District to license the

telescoping weir to commercial entities. It is expected that the telescoping weir will be fully licensed

to commercial vendors by mid-2000.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |