|

||

|

|

||

| |||||||||||||||

|

|

mound was created by point dumping at a taut-moored buoy, the New Eng-

land District will place the majority (say 65 to 70 percent) of the capping

material in similar fashion. However, the capping material is placed

within 50 to 75 m of the buoy as opposed to the 25-m limit used for the

contaminated material. The remaining 30 to 35 percent of the material is

spread around the outer edge of the mound, say 100 to 150 m from the

buoy.

Spreading over large areas

For larger projects, a series of specific lanes can be defined to spread

the capping material. This technique is generally used when the sand is

sprinkled. The sprinkling can be accomplished by cracking the hull of the

barge or split-hull hopper dredge or by direct pumpout from a hopper

through over-the-side pipes. The most straight-forward method to deter-

mine lane spacing for the cracked-hull technique is to compute the foot-

print from an individual load using either the Multiple Dump Fate of

Dredged Material (MDFATE) or Short-Term Fate (STFATE) model (see

Chapter 6 and Appendixes D and E). Of interest will be the footprint's

maximum thickness, maximum width, and width at 0.5 the maximum

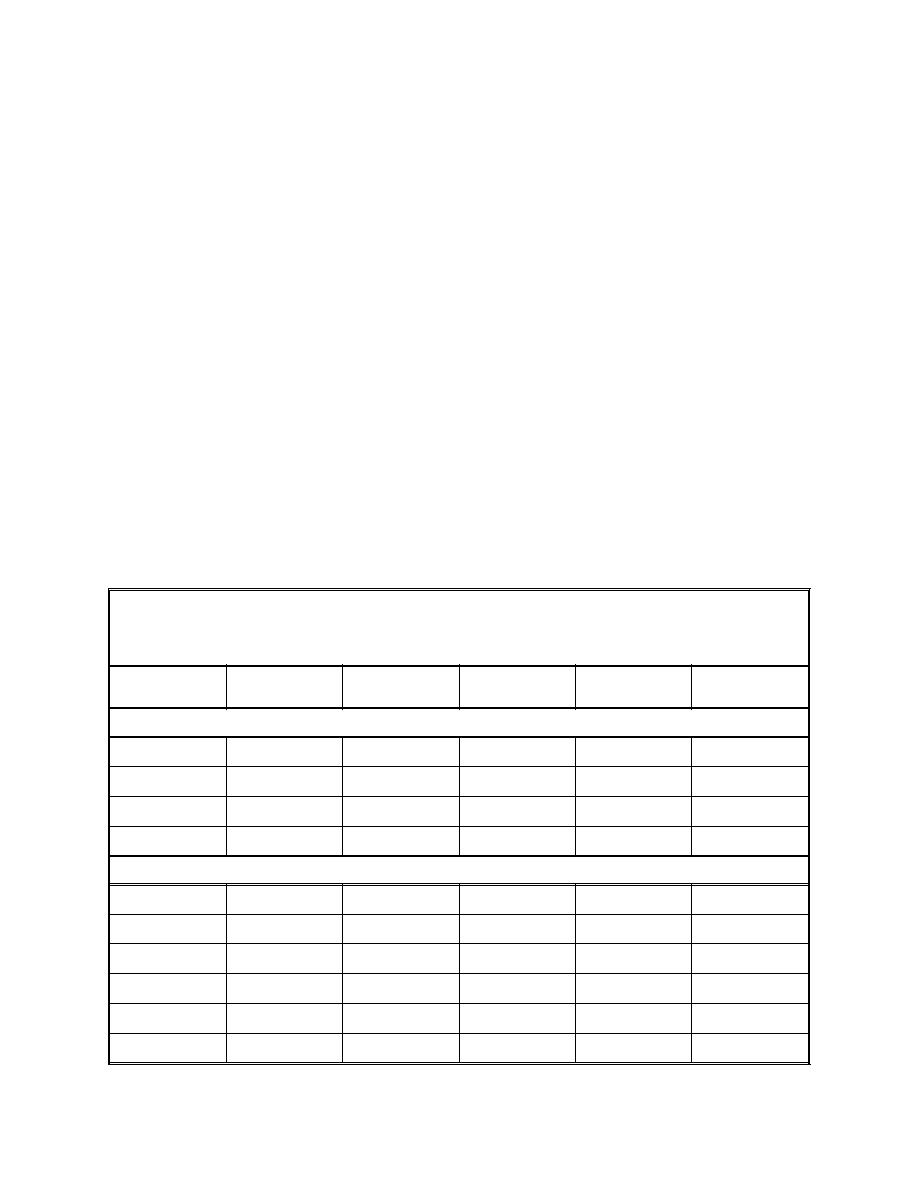

thickness. Table 5 shows the results of MDFATE runs used to design the

capping operation for the Port Newark/Elizabeth project. Based on this

information, disposal lanes 30 m (100 ft) wide, or approximately equal to

the maximum width of the footprint predicted by the model lanes, were

Table 5

Summary of Modeling Results for Capping Contaminated Sediments Using the

Split-Hull Hopper Dredge Dodge Island and Hopper Barge Long Island

Dredge Speed

Disposal Time

Maximum

Maximum Width

Width at 0.5 Max

Disposal Type

m/s

min

Thickness, cm

m

Thickness, m

Split-Hull Hopper Dredge Dodge Island

Cracked hull

1.54

20

4.3

32.0

18.3

Cracked hull

1.54

30

2.7

32.0

18.3

Cracked hull

1.03

20

6.4

41.0

18.8

Cracked hull

1.03

30

4.3

32.0

18.3

Hopper Barge Long Island

Counterflow

0.51

120

7.3

155.4

64.0

Counterflow

1.03

120

3.0

155.4

82.2

Counterflow

0.51

180

4.9

137.2

64.0

Counterflow

1.03

180

2.0

137.2

82.2

Counterflow

0.51

180

4.9

137.2

64.0

Counterflow

1.03

180

2.0

137.2

82.2

47

Chapter 5 Equipment and Placement Techniques

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |