|

||

|

|

||

|

Page Title:

Table 3. Physical Properties of Dump Scow Sediment Samples |

||

| |||||||||||||||

|

|

ERDC TN-DOER-D2

September 2004

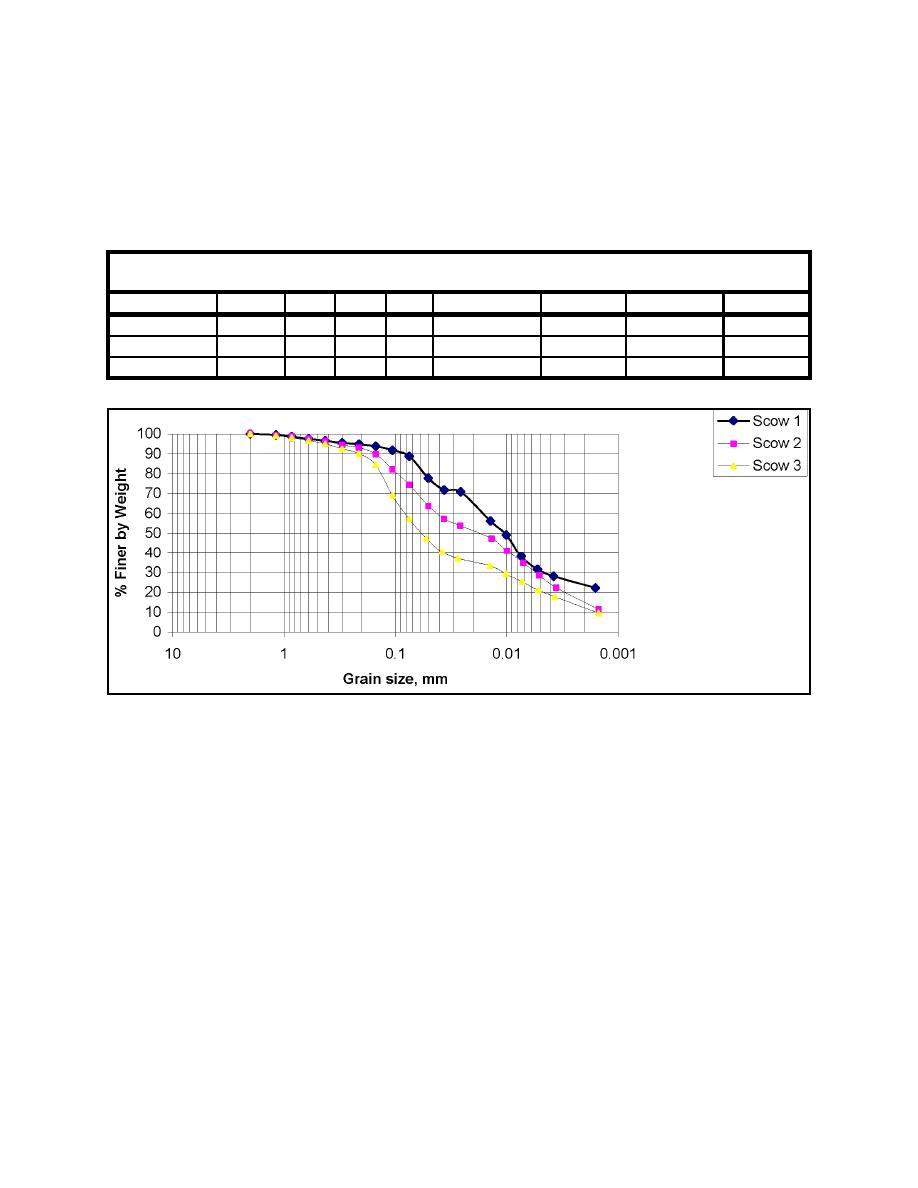

Dump Scow Samples. Three 5-gallon bucket samples were collected from different locations

within a full barge of material dredged from a separate location in the Boston Harbor. A grab

sample was taken from the surface material in the barge, and two clamshell bucket samples were

obtained from within the barge material (SAIC 2000). The samples were analyzed and their

physical properties are shown in Table 3. Figures 4 and 5 show the grain size distributions, and

Table 4 shows the median and mean grain sizes.

Table 3

Physical Properties of Dump Scow Sediment Samples

Sample

Gs

LL

PL

PI

% sand

% silt

% clay

Class

Scow 1

2.33

77

37

40

11

57

32

MH

Scow 2

2.63

56

24

32

26

46

28

CH

Scow 3

2.63

40

35

5

43

36

21

ML

Figure 4.

Cumulative grain size distribution (by weight) curves for dredged material samples taken from

three points in the dump scow during one load cycle

Each sample taken from different locations within a single dump scow load has a progressively

larger median grain size, mean grain size, and sand percentage. The liquid limits, plasticity indi-

ces, and fine grain percentage progressively decrease. Each sample also has a different soil

classification. All three samples are fine-grained and visually appear to be identical.

Variability in physical properties such as Atterberg limits and grain size distribution has an

impact on the engineering behavior of the dredged materials. Figure 6, based on the liquidity

index (water content percent minus PL divided by PI), indicates that the material with the lowest

liquid limit and highest sand content (Scow 3) has a slightly higher shear strength at water

contents above its liquid limit than the other two materials. For example, if the end use of the

dredged materials was to build an upland dike, the materials represented by the Scow 3 sample

probably would exhibit higher slope stability (and factor of safety) at initial water contents above

the liquid limit than the other two materials. It is also possible that a higher rate of strength gain

with time (due to drying) would be observed in a Scow 3 dike if all three materials were initially

deposited wetter than their respective liquid limits, although additional testing would be required

to validate these engineering behavior assumptions prior to designing with the Scow 3 material.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |