|

||

|

|

||

|

Page Title:

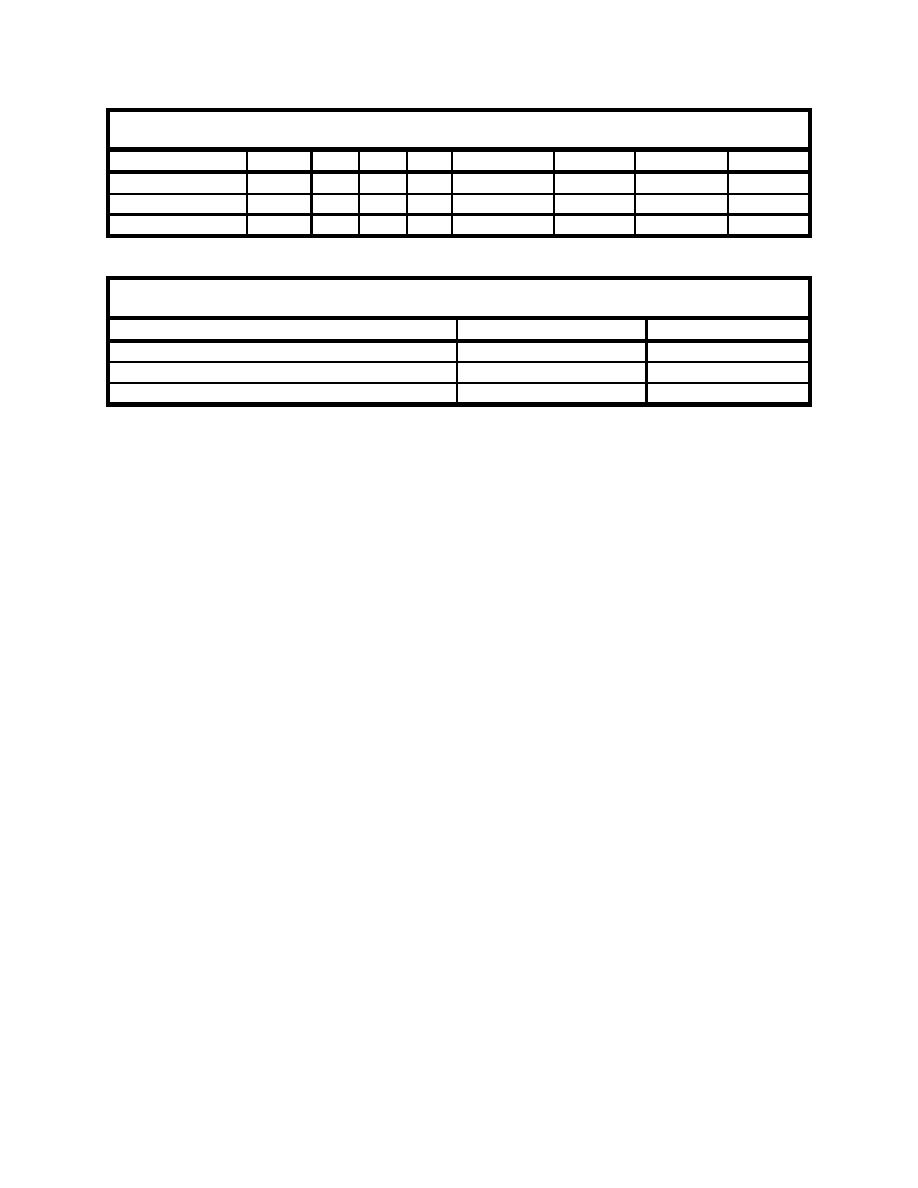

Table 7. Physical Properties of Sediment Grab Samples |

||

| |||||||||||||||

|

|

ERDC TN-DOER-D2

September 2004

Table 7

Physical Properties of Sediment Grab Samples

Sample

Gs

LL

PL

PI

% sand

% silt

% clay

Class

LA Riv

2.66

-

-

-

90

10

0

SP

Fill

2.67

-

-

-

54

27

19

SM

Foundation

2.75

71

36

35

2

48

50

MH

Table 8

Median and Mean Grain Size (by weight) for Sediment Grab Samples

Sample

Median, mm

Mean, mm

LA River material

0.42

0.79

Dredged fill material in pit

0.09

0.18

Foundation material

0.005

0.018

The original sediment appears to have been transformed from a poorly graded sand into a silty

sand material by the time it was deposited into the subaqueous pit and subsequently sampled.

Several reasons may account for this change. Spatial particle size distribution variability in the

pit may have occurred as the coarser-grained material filled the pit bottom prior to the finer-

grained material (winnowing), sampled materials may have a high degree of grain-size heteroge-

neity, or sediment mixing with the soft fine-grained foundation material may have occurred. The

most likely scenario was sediment mixing and displacement of the very soft foundation material.

Modeling the foundation material's stressdisplacement as a function of cap stress (overburden

weight) demonstrated upward and outward displacements of the soft foundation material at the

sideslope interfaces with the dredged fill material (Lee 2001).

Regardless of the reasons for material property changes due to dredging operations, the lessons

illustrated here are that those changes do occur and must be accounted for in proportion to the

importance of quantifying subsequent engineering behavior changes. It may not be important to

know that dredged fill grain size distributions may change unless quantifying the subsequent

engineering behavior in that fill is important. As an example, porosity is only one of the many

material properties influenced by grain size distribution variability. Changes in porosity may not

need to be known for routine maintenance dredging, but computer models for water quality and

environmental fate depend on accurate porosity values.

VARIABILITY DUE TO DEFINITIONS: In addition to the changes in geotechnical properties

and engineering behavior in dredged materials, there are uncertainties in assigning property

parameters based on possible alternate definitions of those parameters. For example, the physical

property of water content may be defined in two or three different ways, depending on the test or

reporting method.

The standard method for water content (ASTM 1998) calculates the weight of water divided by

the weight of dry solids. Alternate but commonly used methods calculate the weight of water

divided by the total wet weight, or by a volumetric basis. Figure 15 compares three definitions of

water content referenced to the geotechnical standard (ASTM method):

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |