|

||

|

|

||

|

Page Title:

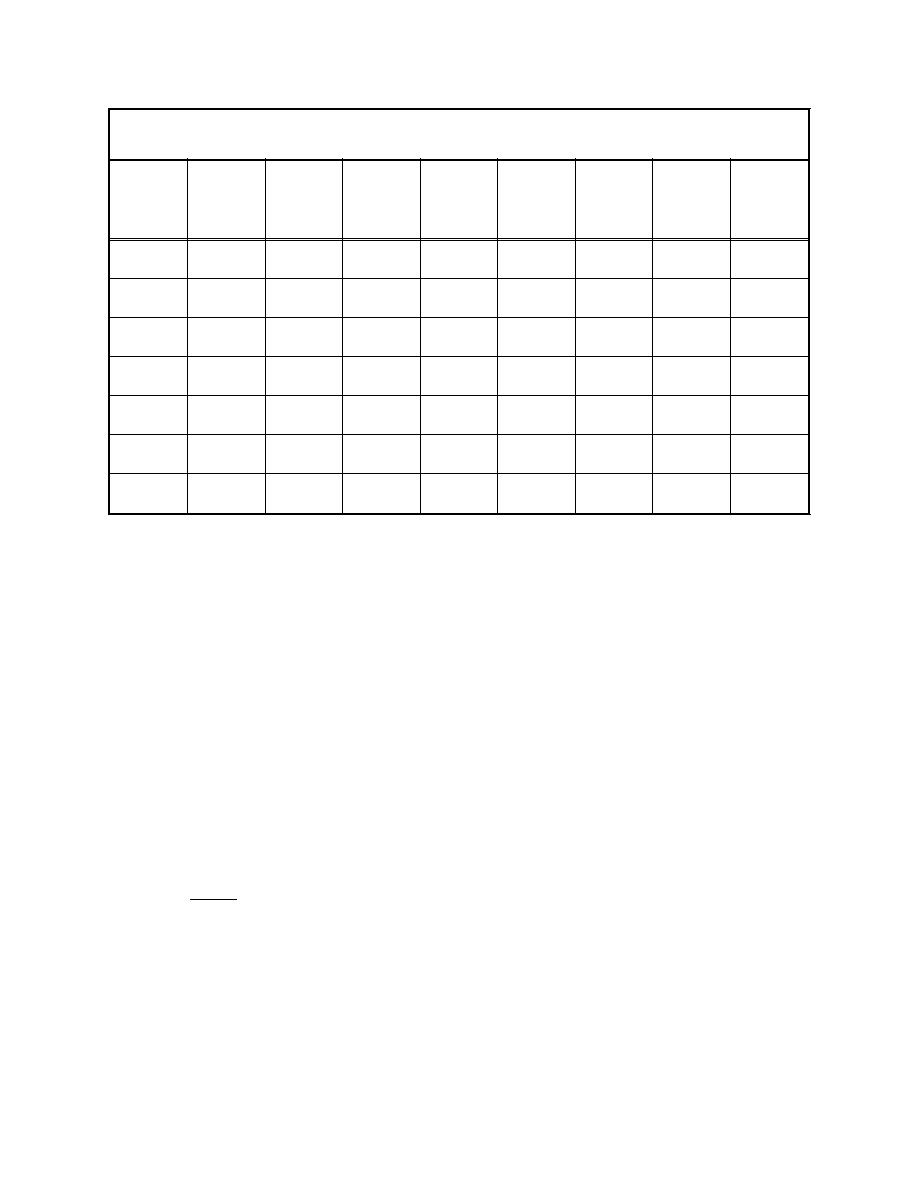

Table 1. Cutterhead Cycle Data - Actual and Estimated Slurry Density and Production |

||

| |||||||||||||||

|

|

ERDC TN-DOER-I3

July 2000

Table 1

Cutterhead Cycle Data - Actual and Estimated Slurry Density and Production

ρmat

ρcyc

PRO

ρmat

ρcyc

V

PRO

Model

Model

Model

g/cm3

g/cm3

g/cm3

g/cm3

m3/hr

m3/hr

m/sec

(lb/ft3)

(lb/ft3)

(lb/ft3)

(lb/ft3)

(yd3/hr)

(yd3/hr)

Ceff

(ft/sec)

Cyc

1

75

1.16

1.12

1.12

1.09

6.95

876

657

(72.38)

(69.89)

(69.89)

(68.02)

(22.8)

(1,145)

(859)

2

76

1.17

1.13

1.12

1.09

6.86

938

649

(73.00)

(70.51)

(69.89)

(68.02)

(22.5)

(1,226)

(848)

3

75

1.20

1.15

1.12

1.09

6.74

1,063

638

(74.88)

(71.76)

(69.89)

(68.02)

(22.1)

(1,389)

(834)

4

79

1.19

1.15

1.12

1.09

6.74

1,063

638

(74.26)

(71.76)

(69.89)

(68.02)

(22.1)

(1,389)

(834)

5

78

1.18

1.14

1.12

1.09

6.77

996

640

(73.63)

(71.14)

(69.89)

(68.02)

(22.2)

(1,302)

(836)

6

79

1.19

1.15

1.12

1.09

6.74

1,063

638

(74.20)

(71.76)

(69.89)

(68.02)

(22.1)

(1,389)

(834)

Avg

77

1.18

1.14

1.12

1.09

6.80

1,000

643

(73.63)

71.14)

(69.89)

(68.02)

(22.3)

(1,307)

(840)

in suspension where they will overflow the hopper. Generally, hopper dredges employ low head,

high capacity pumps because of short discharge line lengths. Conversely, cutterhead dredges must

generate relatively higher discharge heads for the longer line lengths. The hopper dredge is therefore

suction line limited on solids entrainment and transport. Suction line losses such as digging depth,

drag head entrance loss, and sediment friction loss as well as the speed that the dredge operates will

determine the concentrations of solids that can be transported.

Hopper Dredge Monitoring System Components. To monitor the effectiveness of solids

entrainment and load production, a production meter (velocity and density gauge) can be used in

conjunction with load and hopper volume measurement instrumentation (Scott 1993). The average

density of slurry pumped into the hopper dictates the load production. The average density can be

computed by both the density gauge and the combination of load and volume measurement. The

average density in the hopper per load computed by the density gauge is computed by:

Nload

∑ ρs

ρload =

0

(6)

Nload

where

ρload

= the average load slurry density in g/cm3

ρs

= measured slurry density in g/cm3

Nload

= number of data points in load

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |