|

||

|

|

||

|

Page Title:

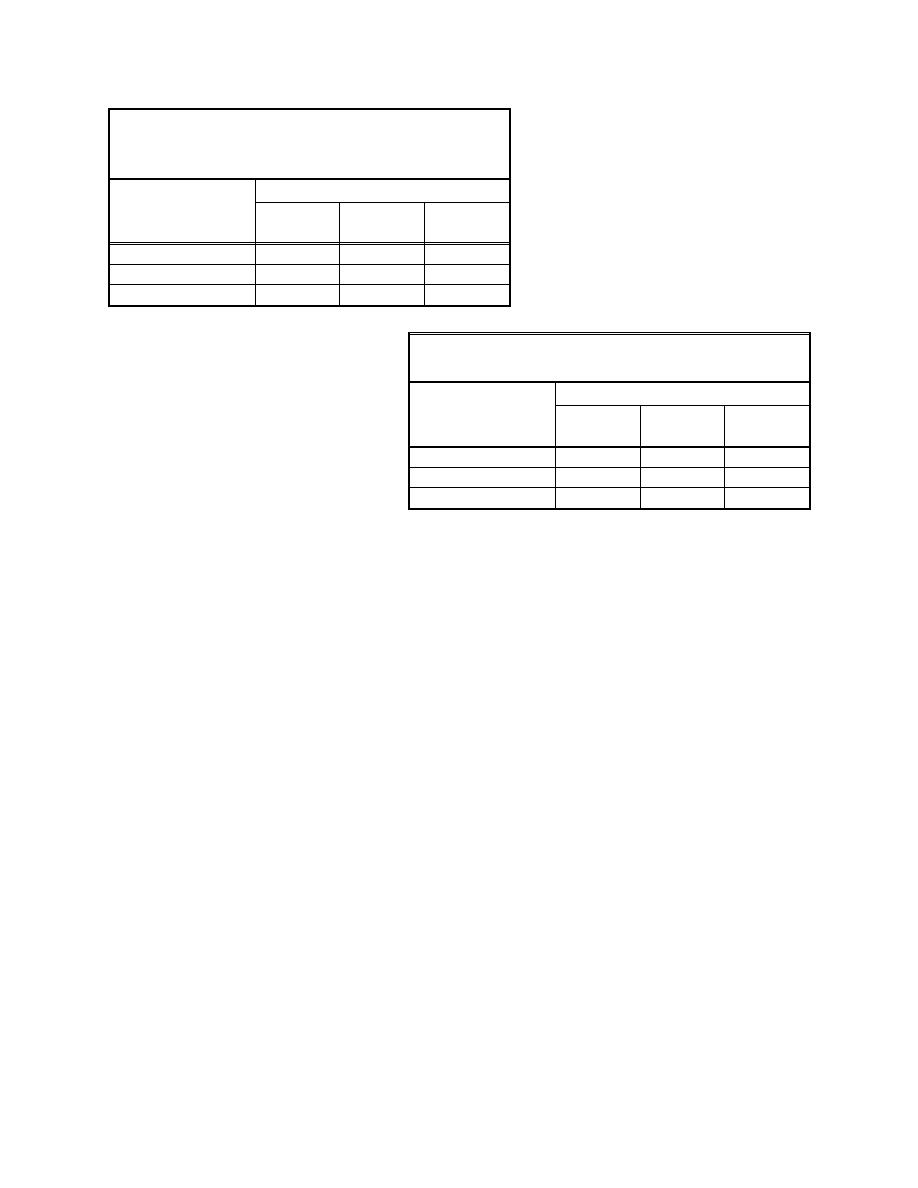

TAble 2. Sediment and Water Variables and Uncertainties |

||

| |||||||||||||||

|

|

ERDC TN-DOER-I5

August 2000

calculations it is assumed that the hop-

Table 2

per dredge is filled to volume (6,122 m3)

Sediment and Water Variables and

and that the load is at the maximum

Uncertainties

272,160 kg. The Case 1 calculation rep-

Variables

resents the "ideal" situation where the

ρm

ρi

ρw

instruments are all calibrated, and the

(g/cm3)

(g/cm3)

(g/cm3)

Values

density of the sediments (mineral and in

Nominal

2.65

1.80

1.00

situ) and associated water has been

High Uncertainty (U)

0.08

0.18

0.03

measured (low uncertainty). The Case

Low Uncertainty (U)

0.03

0.36

0.01

2 calculation is for instruments that are

all properly calibrated, but the sediment Table 3

and water properties are estimated and Hopper Dredge Variables and Uncertainties

therefore have a high degree of uncer-

Variables

ρh

tainty. Case 3 consists of a calculation

Vh

Wh

(g/cm3)

(m3)

(g/cm3)

where the instruments are out of calibra-

Values

tion (high uncertainty), and the sediment Nominal

1.20

6122.0

272160.0

and water densities are measured. The High Uncertainty (U) --

306.0

13608.0

final case (Case 4) represents the worst Low Uncertainty (U)

--

61.2

2721.6

case situation, where the instruments are

not calibrated, and the sediment and water densities are estimated (high uncertainty). The pipeline

dredge uncertainty calculations (volumetric flow rate and solids flow rate) are found in Table 4, and

the hopper dredge calculations (in situ volume content and solids content of the hopper) are found

in Table 5.

The pipeline uncertainty calculations reveal two important considerations. First, if the sediment

properties are well defined, and the instruments correctly calibrated (the ideal case), an acceptable

6 percent uncertainty in the production of the dredge can be realized. Secondly, the accuracy of the

sediment and water properties, primarily the in situ density, are the primary factors in influencing

the total accuracy of the calculation. Because of the inherent accuracy of the density and flow

velocity instrumentation, the in situ sediment density, with its wide range of uncertainty (conserva-

tively 2 to 10 percent) dominates the accuracy of the calculations. The in situ density can actually

vary up to 40 percent (1.2 to 2.0 g/cm3) depending on the sediment type and dredging environment.

The Case 3 calculation reveals that even when the instruments are out of calibration, the uncertainty

(8 percent) is reasonable with known sediment and water properties. The solids flow rate

calculations are more accurate because the mineral density of solids only varies to about a

maximum of 4 percent. The solids flow rate calculations indicate that the water density is the

dominant variable in affecting the production accuracy. The Case 4 calculation reveals an error

potential for volumetric production calculations as high as 25 percent if the instruments are not

properly calibrated and the sediment and water properties are not well defined.

The hopper production equations reveal the opposite trend. Because the measured density in the

hopper is dependent on the measurement of the draft of the vessel (pressure transducers), and the

volume in the hopper (ultrasonic water level transducers), the uncertainty in the production

calculation is sensitive to the calibration and proper operation of the instruments. For the volume

content calculations, the in situ density of the sediments has the greatest influence on the calculation

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |