|

||

|

|

||

|

Page Title:

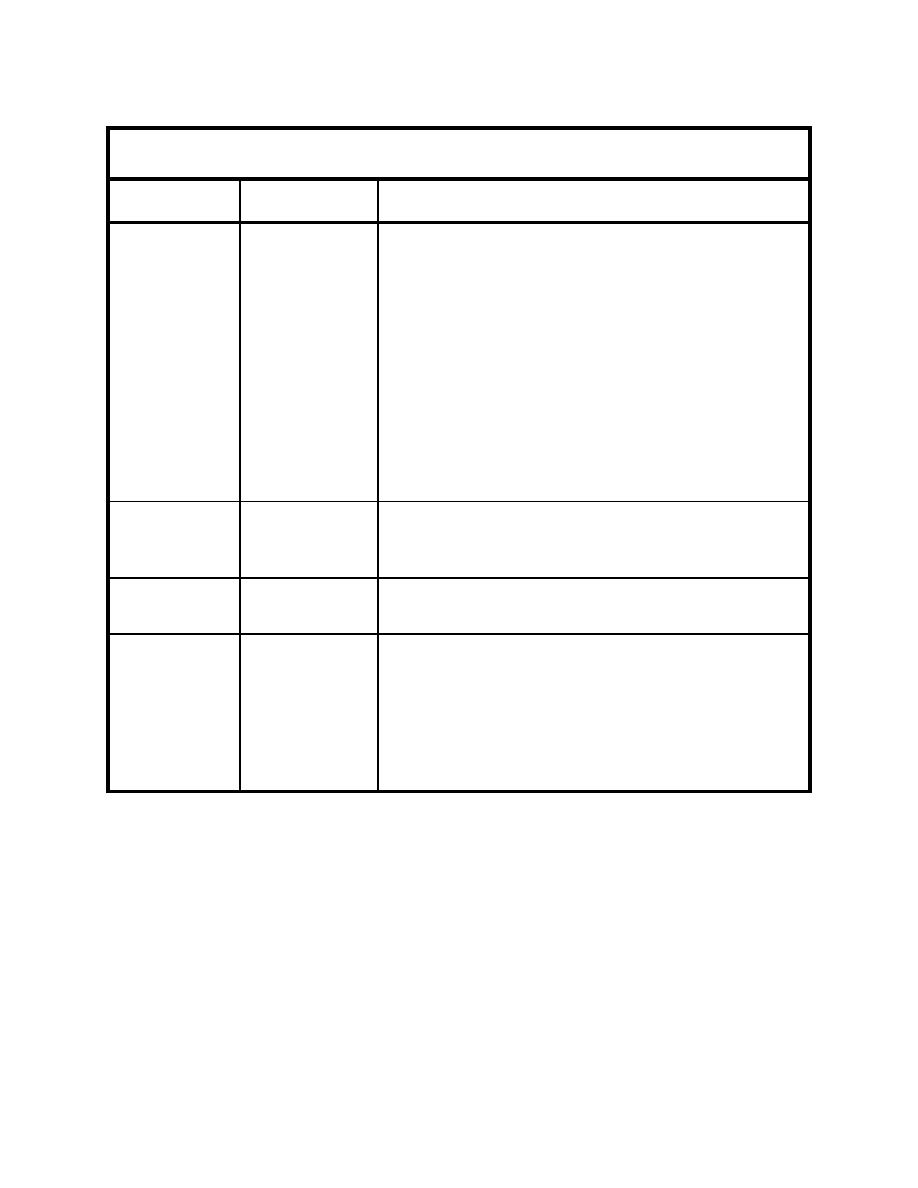

Table 8. Data Requirements and Testing for Leachate Collection Systems |

||

| |||||||||||||||

|

|

ERDC TN-DOER-R6

December 2004

Table 8

Data Requirements and Testing for Leachate Collection Systems

ASTM Procedures

Comments

Requirement

and References

Granular materials

USEPA 1992a

granular materials used for the drainage layer for waste piles and

landfills and 1x10-1 cm/sec for granular materials used in surface

impoundments. Most clean, free-draining sands and gravels function

adequately as drainage layers for leachate collection systems. Those

soils which function best as drainage layers normally contain less

than 6 percent by weight (74 microns or 0.0029 inches) passing the

No. 200 sieve (U.S. Standard) and have a hydraulic conductivity

greater than 10 cm/s. Soils which contain higher fractions of fines

may function adequately during the initial phases of the operation,

but experience has shown that these soils are more susceptible to

clogging as a result of biological activity and saturation from the

leachate. Gravel installed with particle sizes that are too small tend

to "sift" into the waste leaving a void. Those with grain-size

distributions that are too large tend to entrain and accumulate fine

particulate matter that can either clog the drainage layer or the filter

fabric around the layer.

Synthetic materials

USEPA 1992a

Synthetic materials used in drainage layers require a minimum

hydraulic transmissivity of 3x10-5 m2/sec for waste piles and landfills

impoundments.

Geonets

ASTM D4716-00

Used as lateral drainage layers in leachate collection systems,

geonets serve as high-hydraulic-conductivity corridors for leachate

(ASTM 2000c)

transport.

Soil retention and adequate permeability are required for proper

function of geotextiles to filter leachate and separate soil, dredged

material, and other liner materials from the drainage layers.

USEPA 1992a

Permeability

ASTM 4751-99a

Soil retention

(ASTM 1999b)

Costs. Liner costs are directly related to the areal size of the CDF. The larger the CDF, the greater the

amount of liner materials and construction effort required. A careful study of the tradeoff between areal

footprint and hydraulic efficiency to enhance suspended solids removal is required, as outlined in USACE

(1987). For example, using spur dikes to increase hydraulic efficiency can reduce the areal footprint,

resulting in reduced liner costs. USACE models DYECON (Hayes and Schroeder 1992a) and SETTLE

(Hayes and Schroeder 1992b) are also available to assist the designer in this regard. A second factor in

liner costs is the selection of liner materials. As illustrated in Table 9, qualitative costs for liner systems

range from the least cost (clean dredged material) to the most expensive (composite liner system).

Additional cost considerations include site accessibility (mobilization and demobilization) and labor and

material costs of the geographic region.

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |