|

||

|

|

||

|

Page Title:

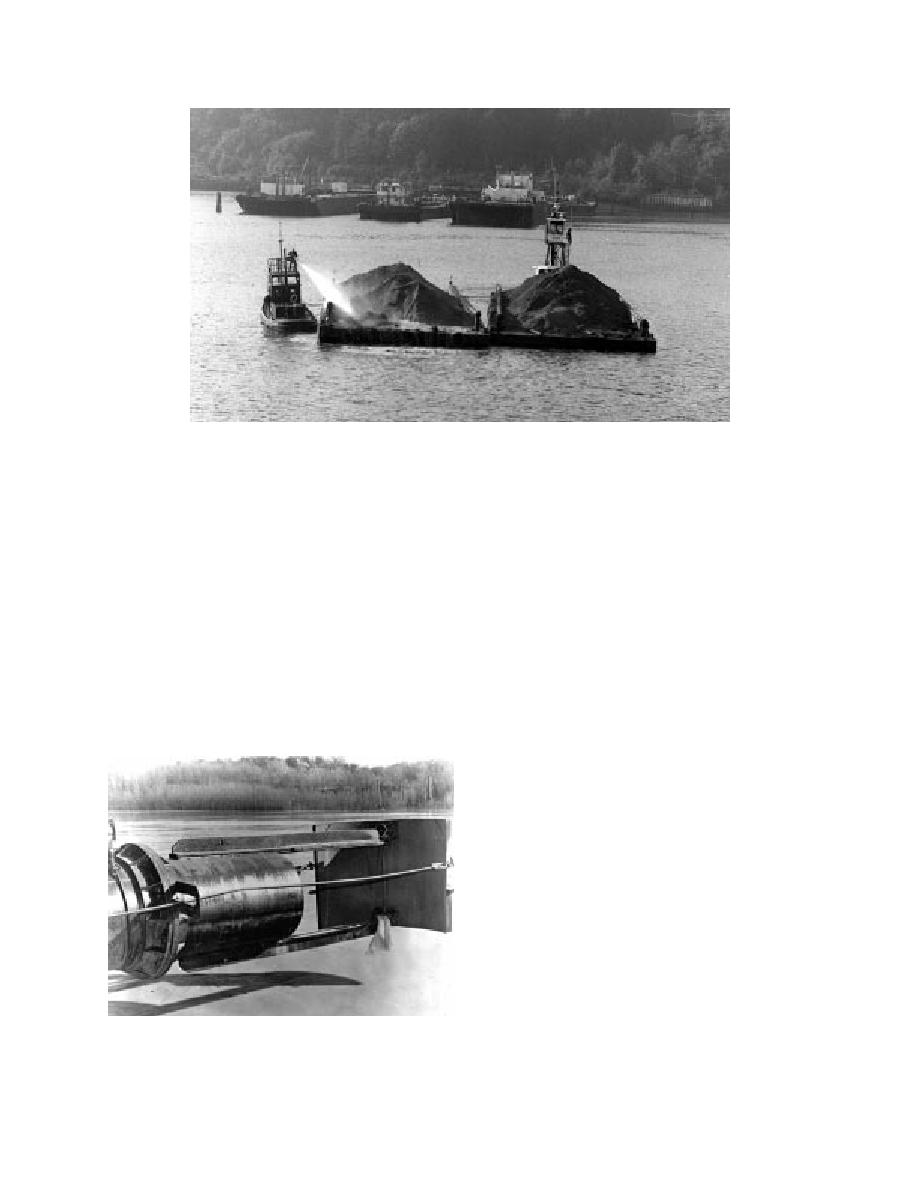

Figure 5. Pressure-hose washing method of placement |

||

| |||||||||||||||

|

|

Figure 5. Pressure-hose washing method of placement

plates to force the slurry into the direction the vessel was traveling. As

with the cracked-hull method described above, injecting the slurry into the

direction of travel of the vessel increased turbulence, reducing the down-

ward velocity of the slurry particles and thus the potential for resuspen-

sion of the contaminated sediments. Computer models (see Chapter 6)

were used to predict the width of coverage from a single pass and the

maximum thickness produced (Randall, Clausner, and Johnson 1994).

Pipeline with baffle plate or sand box

Spreading placement for capping operations can be easily accomplished

with surface discharge from a pipeline aided by an energy-dissipating de-

vice such as a baffle plate or sand box attached to the end of the pipeline.

Hydraulic placement is well suited

to placement of thin layers over

large surface areas.

A baffle plate (Figure 6), some-

times called an impingement or

momentum plate, serves two func-

tions. First, as the pipeline dis-

charge strikes the plate, the

discharge is sprayed in a radial

fashion; the discharge is allowed

to fall vertically into the water

column. The decrease in velocity

reduces the potential of the dis-

charge to erode material already

in place. Second, the angle of the

plate can be adjusted so that the

Figure 6. Spreader plate for hydraulic pipeline

momentum of the discharge exerts

discharge

32

Chapter 5 Equipment and Placement Techniques

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |