|

||

|

|

||

| |||||||||||||||

|

|

Design specifications for this sub-

merged diffuser system are available

(Neal, Henry, and Greene 1978;

Palermo, in preparation).

A variation of the DMRP diffuser

design was used in an equipment

demonstration at Calumet Harbor, Illi-

nois. Although not constructed to the

DMRP specifications, this diffuser

significantly reduced pipeline exit ve-

locity, confined the discharged mate-

rial to the lower portion of the water

column, and reduced suspended sol-

ids in the upper portion of the water

column (Hayes, McLellan, and Truitt

1988). Diffusers have been con-

structed using the DMRP design and

used at a habitat creation project in

the Chesapeake Bay (Earhart, Clark,

and Shipley 1988) and at a Superfund

pilot dredging project at New Bed-

ford Harbor, Massachusetts, involv-

ing subaqueous capping (USACE

1990). At the Chesapeake Bay site,

the diffuser was used to effectively

achieve dredged material mounding

prior to placement of a layer of oys-

ter shell to provide substrate for at-

tachment of oyster spat. At the New

Bedford site, the diffuser was used to

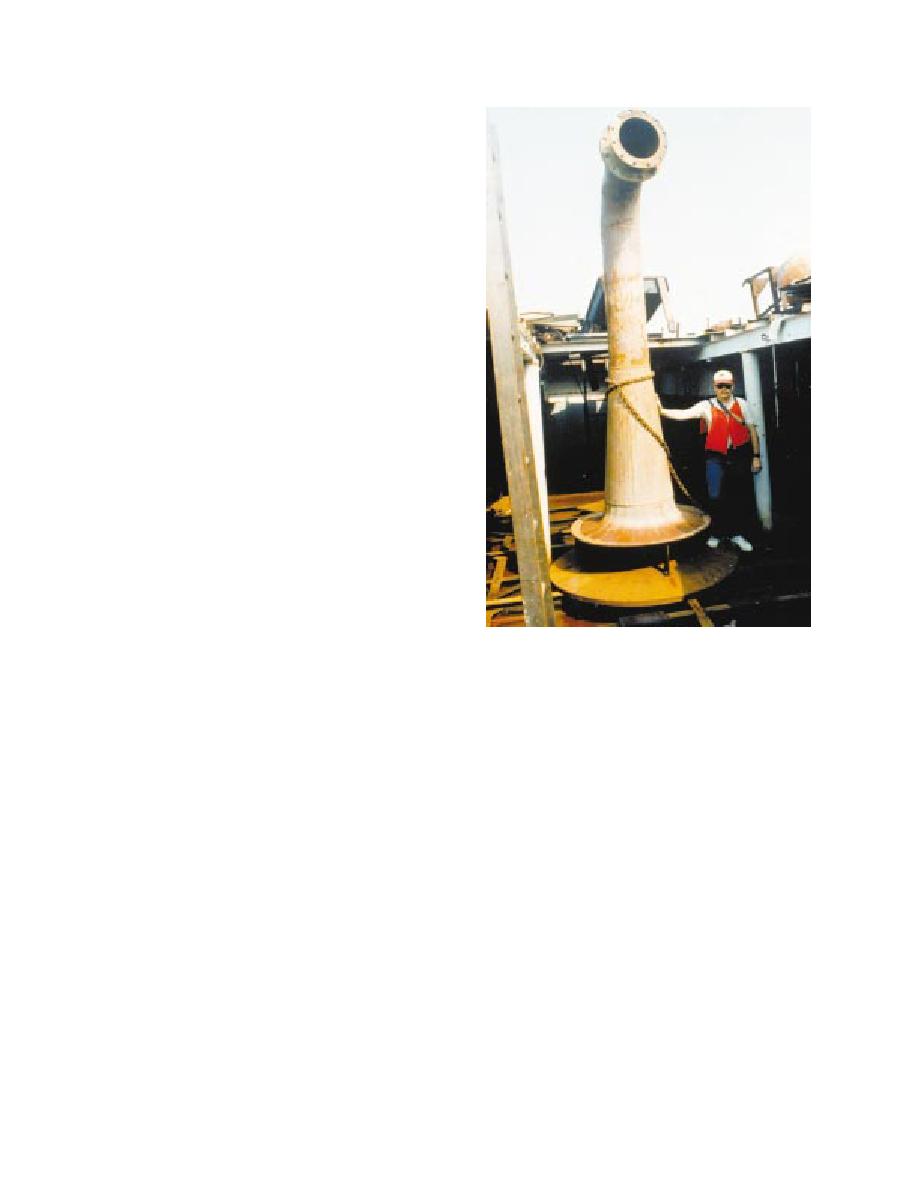

Figure 9. Submerged diffuser

place contaminated sediment in an

excavated subaqueous cell and was effective in reducing sediment resus-

pension and in controlling placement of contaminated sediment. How-

ever, capping operations were started immediately, and positioning of the

diffuser within 2 ft of the contaminated sediment layer resulted in mixing

of cap sediment with contaminated sediment. These results indicate the

need for a high degree of control when capping newly placed slurry with a

diffuser and the need for adequate time to allow for some self-weight con-

solidation of slurry material prior to capping. Diffusers have also been

successfully used to place and cap contaminated sediments at projects in

Rotterdam Harbor in the Netherlands (d'Angremond, de Jong, and de

Waard 1986) and in Antwerp Harbor in Belgium (Van Wijck and Smits

1991).

Sand spreader barge

Specialized equipment for hydraulic spreading of sand for capping has

been used by the Japanese (Kikegawa 1983; Sanderson and McKnight

1986). This equipment employs the basic features of a hydraulic dredge

with submerged discharge (Figure 10). Material is brought to the spreader

by barge, where water is added to slurry the sand. The spreader then pumps

35

Chapter 5 Equipment and Placement Techniques

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |