|

||

|

|

||

|

Page Title:

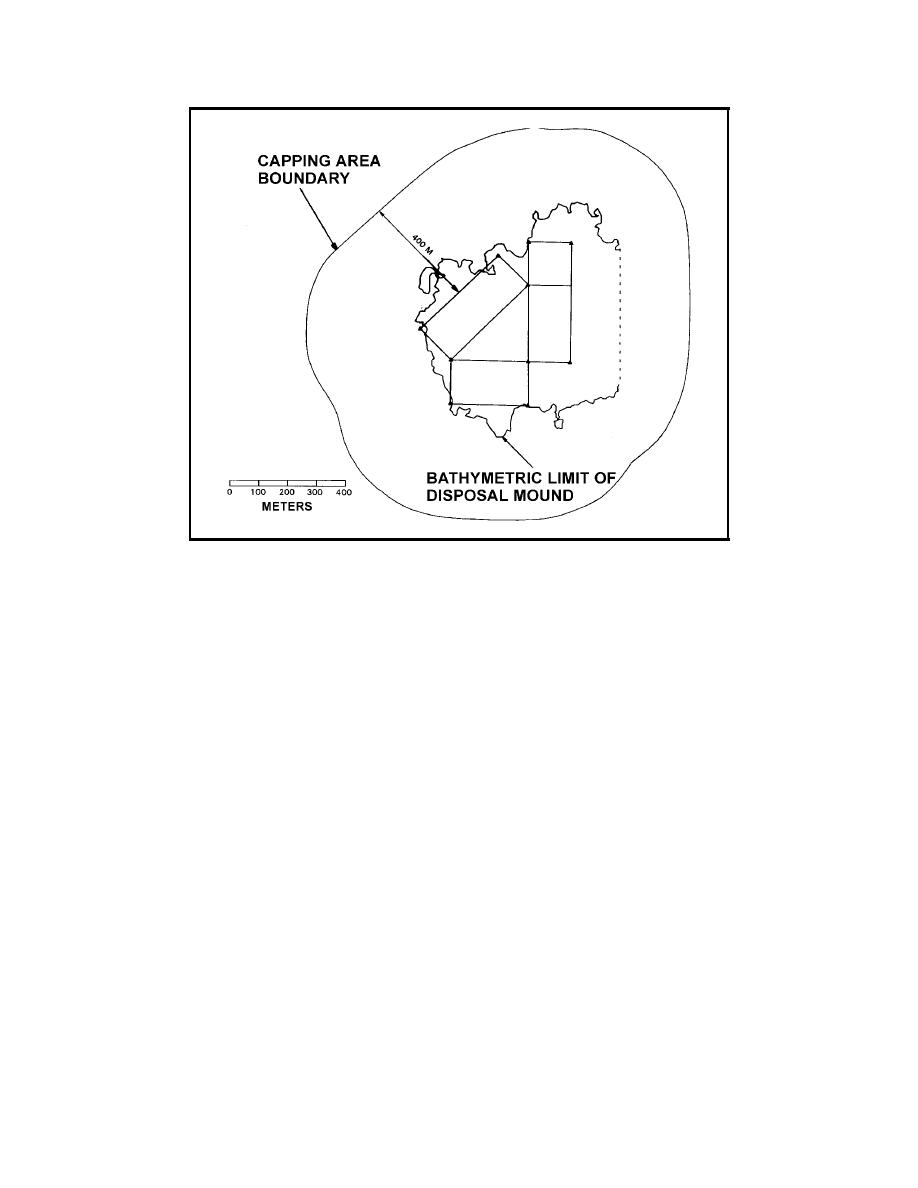

Figure 32. Port Newark/Elizabeth mound limits |

||

| |||||||||||||||

|

|

Figure 32.

Port Newark/Elizabeth mound limits

the barges were recorded. Barge speed during placement was 0.5 to 1.5 m/sec.

To help prevent mounding at the point of release, the barge operators were

directed to crack the hull part way resulting in a disposal time of 30 sec to

1 min, and were also directed to enter the disposal lanes from opposite

ends on alternate placements.

Apex buoys were installed using calibrated LORAN-C so they could be

quickly reset. LORAN-C was calibrated with short-range microwave read-

ings at known points within the harbors.

A bathymetric survey conducted during mound construction indicated

the contaminated material mound was exceeding the desired 1.5-m height

limitation in some locations. This combined with the Port's request to in-

crease the amount of material dredged altered the disposal lane pattern to

include additional placement in the center of the triangle and the addition

of a 150- by 150-m square area at the north end of lane AB (Figure 32).

The final postcontaminated mound bathymetry survey showed that a

roughly triangular mound had been formed as designed. As might be ex-

pected, individual mound peaks were evident (generally located at the

ends of the lanes), which projected above the average mound thickness

over the area of about 1.3 m. The peaks ranged in elevation from 1.5 to

2.4 m. Average side slopes (from the edge of the mound crest down to the

0.2-m contour) on the outer sides of the mounds were about 1:45.

114

Chapter 10 Case Studies

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |