|

||

|

|

||

|

Page Title:

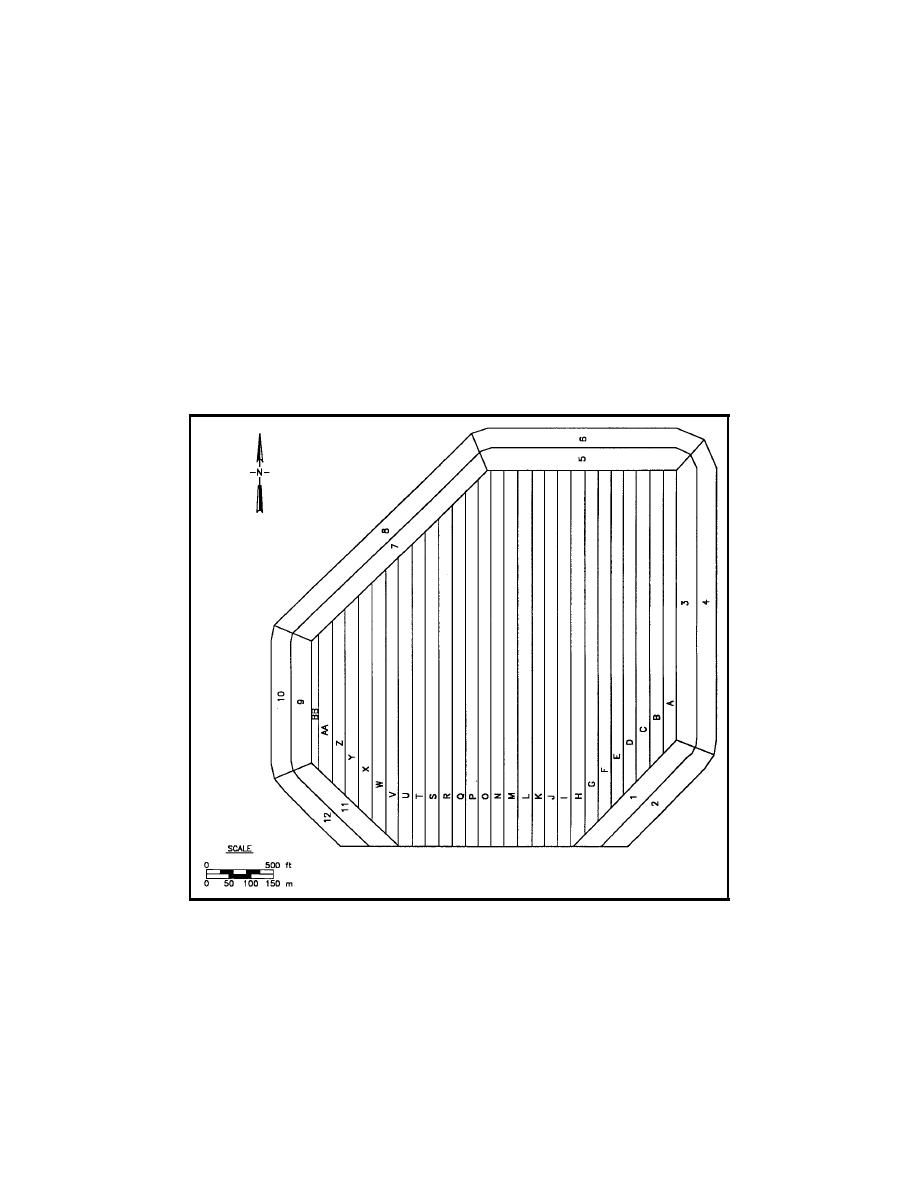

Figure 33. Disposal lanes used for placing cap material in Port Newark/ Elizabeth project |

||

| |||||||||||||||

|

|

of 25 to 30 min while moving at an average speed of 3.0 to 3.7 km/hr with

the hull cracked open 0.3 m. The Long Island pumped out its average

9,200-m3 load through over-the-side pipes with the slurry directed forward

over a period of 2 to 3 hr while moving at 1.9 to 5.6 km/hr.

To uniformly place the material, the dredges followed a series of lanes

30 m wide that covered the contaminated sediment mound and apron.

Turning requirements typically caused the hopper barge to move over four

lanes after reaching the end of a lane. A series of straight-lane segments

around the perimeter were also used to cover the outer edges of the pro-

ject. Disposal-lane orientation varied over the duration of the project. In-

itially, the lanes started north-south; at later stages they were a series of

straight sections around the roughly octagon-shaped perimeter of the pro-

ject (Figure 33). Microwave positioning (with three shore stations) with

an estimated accuracy of 3 m or better was used for navigation and posi-

tioning of the hopper dredges.

Figure 33.

Disposal lanes used for placing cap material in Port Newark/

Elizabeth project

Initial cap placement involved sailing long straight lines, 600 to 900 m

long (with a turn at the end of each line). Cleanup operations, i.e., filling

in small areas that have less than the required thickness, generally in-

volved areas only about 100 m across. Placing sand in these small areas

was much less efficient due to two factors. For the Long Island, maneu-

vering is very difficult, with 20 to 25 min required to turn the vessel

116

Chapter 10 Case Studies

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |