|

||

|

|

||

| |||||||||||||||

|

|

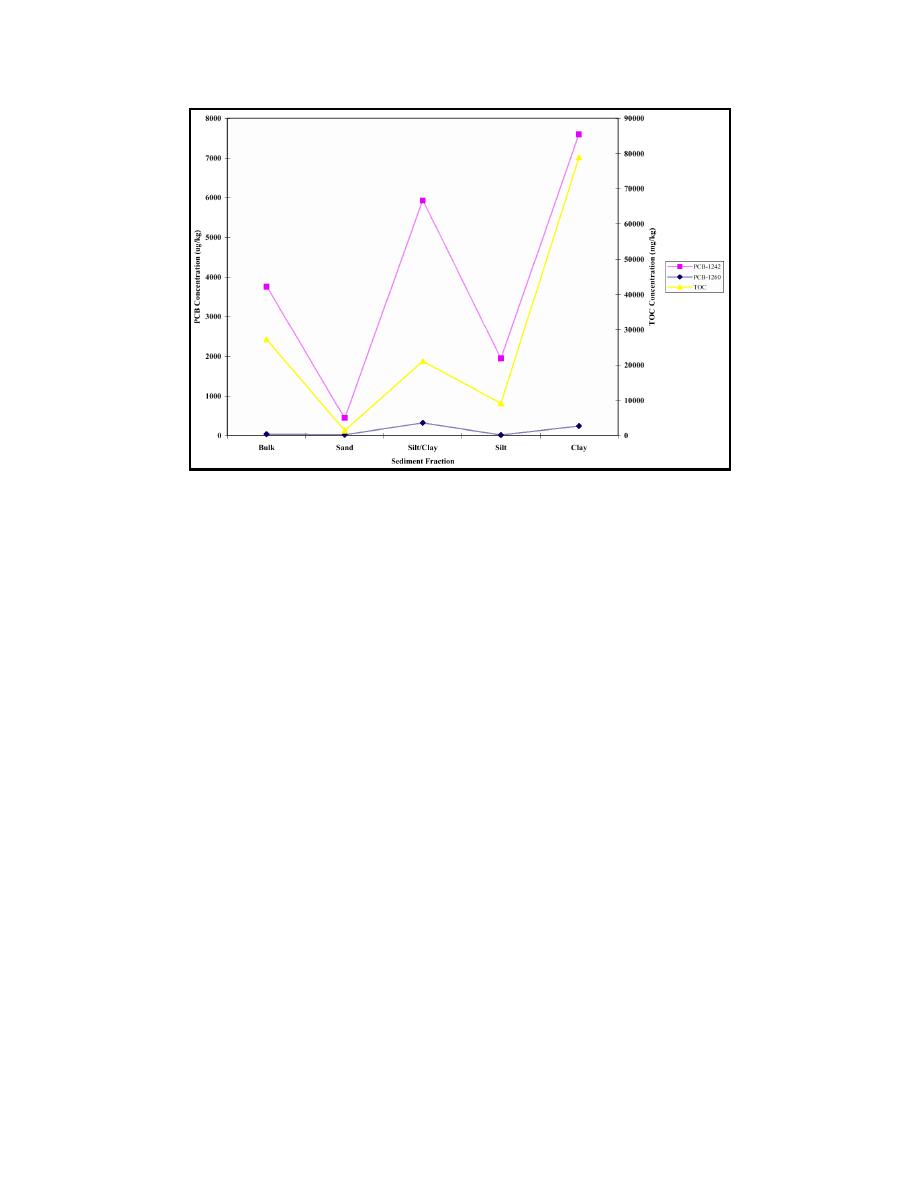

Figure 7.

PCB versus TOC concentrations, Cell 4 material

Site logistics

The Cell 4 staging area was much farther from the freshwater source than the

staging area originally selected for processing the Cell 5 material. Additionally,

the Cell 4 staging area was much smaller than the original site, making onsite

stockpiling of mechanically excavated material infeasible. It was therefore

decided to excavate only a small amount of Cell 4 material for screening testing,

and to excavate feed for the hydrocyclone using a modified jet pump. This was a

particularly attractive alternative because of the potential benefits of small-scale

hydraulic excavation or mechanical excavation (accessibility in unstable material,

maneuverability around debris), and the added information that would result

from a single effort. The principal disadvantage of this approach was that the

process water had to be pumped approximately 300 m (1,000 ft) to the

excavation point.

Equipment

Because of the distance between the staging area and the freshwater source, a

larger water pump, transfer hoses, and generator were required than for the

original staging area. Water pump, generator, and flexible hoses with quick

couplings were available and obtained on a short-term rental basis. The MetPro

mobile unit was as previously described in the section "Project Activities,"

consisting of a trailer, slurry pump, sump, and 0.6-m (24-in.) MDS (Figure 8).

The eductor pump was fitted with an exterior ring, providing water jets for

horizontal excavation (Figure 9). A powerscreen was also rented for screening

the mechanically excavated material (Figures 10 and 11). The unit consisted of a

grizzly, hopper with shredder, conveyer and shaking screen, equipped with a

18

Chapter 2 Project Description

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |