|

||

|

|

||

|

Page Title:

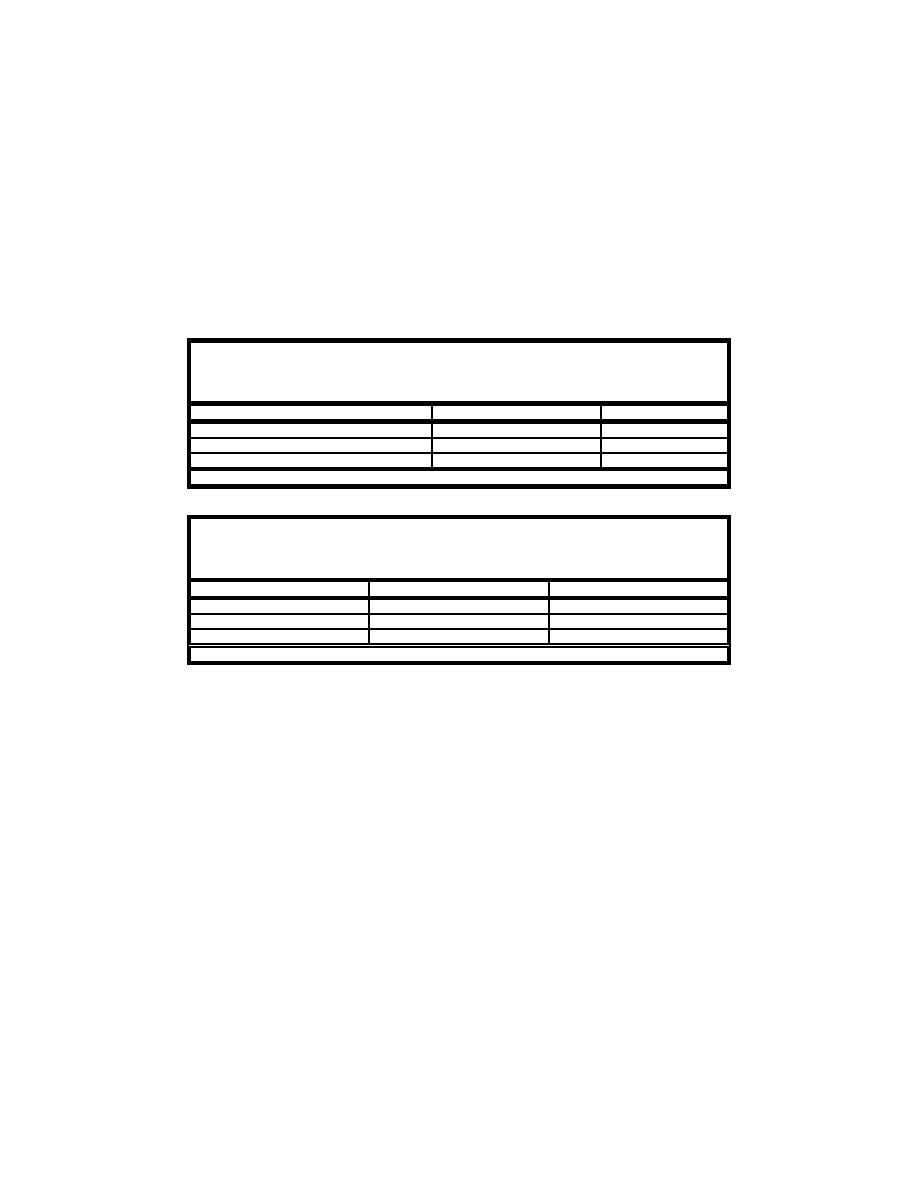

Table C1. Target Suspended Solids and Required Sediment for Simulated Runoff Samples from Wet Sediment |

||

| |||||||||||||||

|

|

analysis of unfiltered runoff samples or from the computations described in

Section 5.3.1.

Step 2a. Wet Sediment Evaluation. The wet sediment evaluation begins

with the placement of replicate wet sediment samples into 4-L glass bottles using

the oven-dry weight equivalents shown in Table C1. Three replicates of each

sediment to water ratio is prepared. Deionized water is added to bring total

sample volume to four liters. The containers are placed horizontally on a

mechanical shaker and agitated for 1 hr to ensure complete suspension of

sediment and sediment to water contact. It is advised to tape the caps to prevent

leakage. After shaking is complete the sample is filtered using appropriate for

Table C1

Target Suspended Solids and Required Sediment for Simulated

Runoff Samples from Wet Sediment

Sediment / 1 L, g1

Sediment: Water Ratio

Suspended Solids, mg/L

1:2,000

500

0.5

1:200

5,000

5

1:20

50,000

50

1

Oven-dry weight equivalent of wet sediment.

Table C2

Target Suspended Solids and Required Sediment for Simulated

Runoff Samples from Dry Sediment

Suspended Solids, mg L-1

Sediment / 1 L, g1

Sediment: Water Ratio

1:20,000

50

0.05

1:2,000

5,00

0.5

1:200

5,000

5

1

Oven-dry weight.

the contaminants in question. Organic contaminants are pre-filtered through a

Whatman GF/D 2.7-um glass fiber filter followed by a Whatman GF/F

0.7-um glass fiber filter or equivalent. Inorganic contaminants are in addition

filtered through a MF-Millipore 0.45-um membrane filter or equivalent.

Preservation of filtered samples is accomplished according to U.S. Environ-

mental Protection Agency (USEPA) standards appropriate for each contaminant.

Step 2b. Dry Sediment Evaluation for Organics and Nutrients. The

purpose of the dry portion of the SLRP is to predict the long-term effects of

drying and oxidation of dredged material on movement of contaminants from

upland CDFs. For the determination of all contaminants except priority metals,

three replicates of air-dried sediment from Step 1b are weighed to the nearest

0.001 g and placed in 4-L bottles as shown in Table C2. An amount of deionized

water equal to the total volume required minus the sediment weight is added to

the bottle and capped. Sediment samples are collected from the sample bucket

and placed in a drying oven at 90 EC for 48 hr. Place the oven-dried sediment in

the 4-L bottles and incrementally add the 30 percent H2O2 until the full volume

required for oxidation has been added. Reactions to the H2O2 vary by sediment

and some may be subject to boil-over. For the 500- and 50-mg l-1 samples,

smaller containers, such as 500- and 50-mL glass beakers, respectively, should

C5

Appendix C Test Procedures for Surface Runoff Discharges

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |