|

||

|

|

||

|

Page Title:

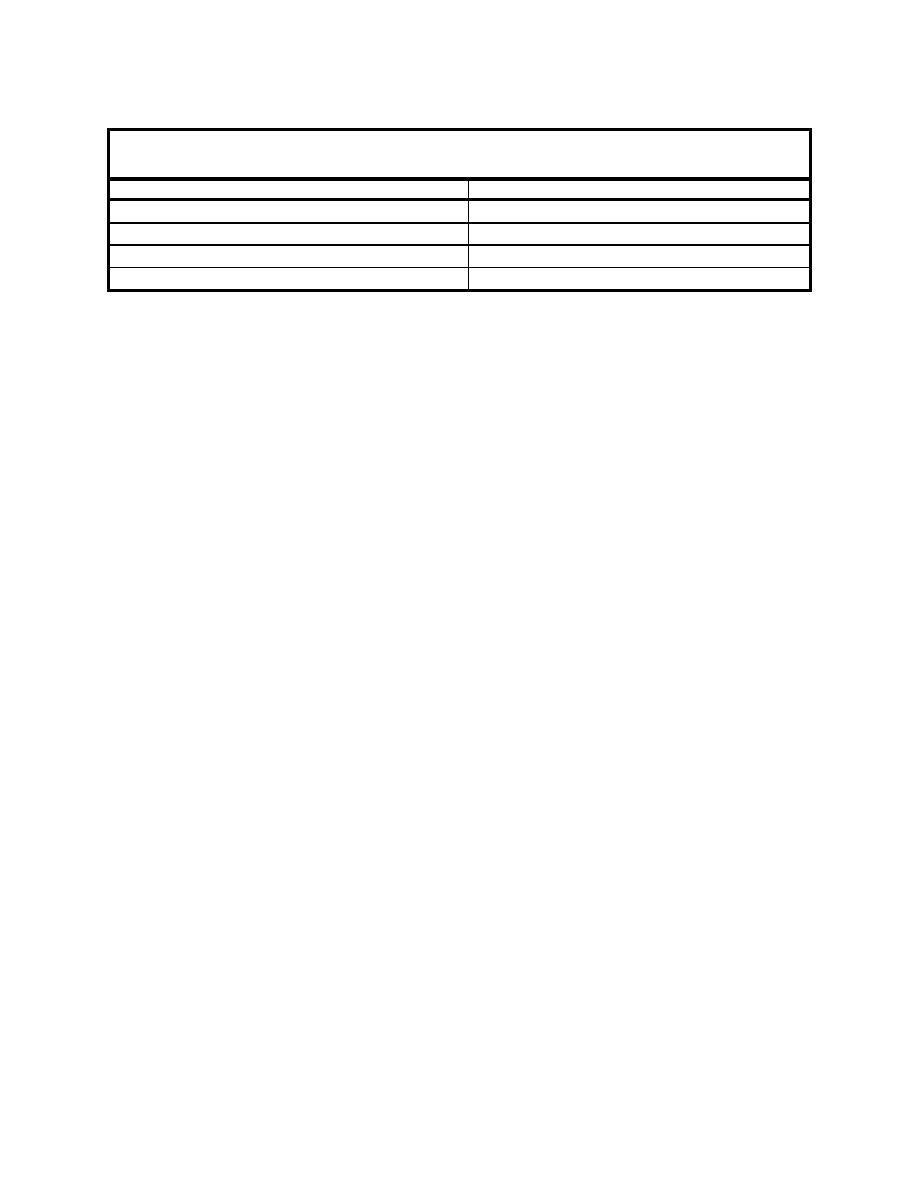

Table 3. Hydraulic Conductivities of Unconsolidated Sediments (after USEPA (1994)) |

||

| |||||||||||||||

|

|

ERDC TN-DOER-R6

December 2004

Table 3

Hydraulic Conductivities of Unconsolidated Sediments (after USEPA (1994))

Material

Hydraulic Conductivity (cm/s)

10-6 to 10-4

Silt, sandy silts, clayey sands, till

10-5 to 10-3

Silty sands, fine sands

10-3 to 10-1

Well-sorted sands, glacial outwash

10-2 to 1

Well-sorted gravel

The relative high cost of transporting and installing borrow materials and the exceptionally high cost of

more advanced liner systems suggest that modification of native soils is an economical option worth

exploring.

If sand is the predominant local material, it may be modified by the addition of bentonite clay. A recent

study by Wareham et al. (1998) suggests that sand deposits may be modified with bentonite clay for a

reduction in hydraulic conductivity of two to four orders of magnitude. Mixing a sodium-modified,

calcium-magnesium bentonite with sand at a ratio of 7.5 percent bentonite clay to 92.5 percent sand, on a

dry-weight basis, reduced the hydraulic conductivity to 10-7 to 10-8 cm/s. Addition of alkaline water (lime

mixed with water to pH 10.1) to achieve an optimum water content of 19.3 percent (maximum dry density

of 1.635 g/cm3) resulted in an optimal separation of bentonite layers, allowing bentonite to fill the void

spaces within the sand and limit the void space available for water movement. Saline water may alter the

Additional guidance on soil and sediment modifications for reduced hydraulic conductivity and increased

shear strength is provided by Daniel and Benson (1990).

Compacted Clay Liner. Compacted clay liners (CCLs) are soil liners consisting of fine-grained

materials possessing hydraulic conductivities of 10-7 cm/s or less (Qian 1995). These materials are used

for bottom liners as well as surface covers to reduce infiltration of precipitation, and the plate-like shape

of the soil grains prevents additional leachate formation. The fineness of the particle size of clay materials

provides a means for individual clay particles to fill pore spaces, thus reducing the overall hydraulic

conductivity of the soil liner. In addition to the low permeability, the high specific surface area of clay

will tend to increase the surface interaction between contaminants and individual particles. This

adsorption and low permeability combine to increase the overall ability of the compacted clay liner to

retain the contaminated material within the CDF.

The clay material used in compacted clay liners may consist of kaolinite, illite, or montmorillonite.

Although each type of clay may be used in low-permeability layers, preference is often given to

montmorillonite. The fineness of the clay particle size, coupled with montmorillonite's ionic surface

charges, provides a large specific surface area material that interacts strongly with polar water molecules.

As the water molecules come into contact with the clay, the water tends to diffuse between individual clay

platelets, causing the platelets to separate and swell apart (Qian 1995). It is this swelling process, coupled

with the tightly-bound water between the platelets, that gives hydrated montmorillonite an extremely low

permeability.

General design criteria for CCLs as liners within land disposal facilities are provided in USEPA (1978,

1988a, 1988b, 1991a, 1992a) and specific guidance for CCLs within CDFs are provided in USACE

(1987). Each design criterion attempts to achieve maximum reduction in hydraulic conductivity based on

material selection, thickness, compactive effort, and moisture content.

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |