|

||

|

|

||

|

Page Title:

MEASUREMENT IN THE PIPELINE (cont.) |

||

| |||||||||||||||

|

|

ERDC TN-DOER-T6

September 2004

A Nuclear Regulatory Commission (NRC) license is required to supervise the use of the nuclear

density gauge (Herbich et al. 1992).

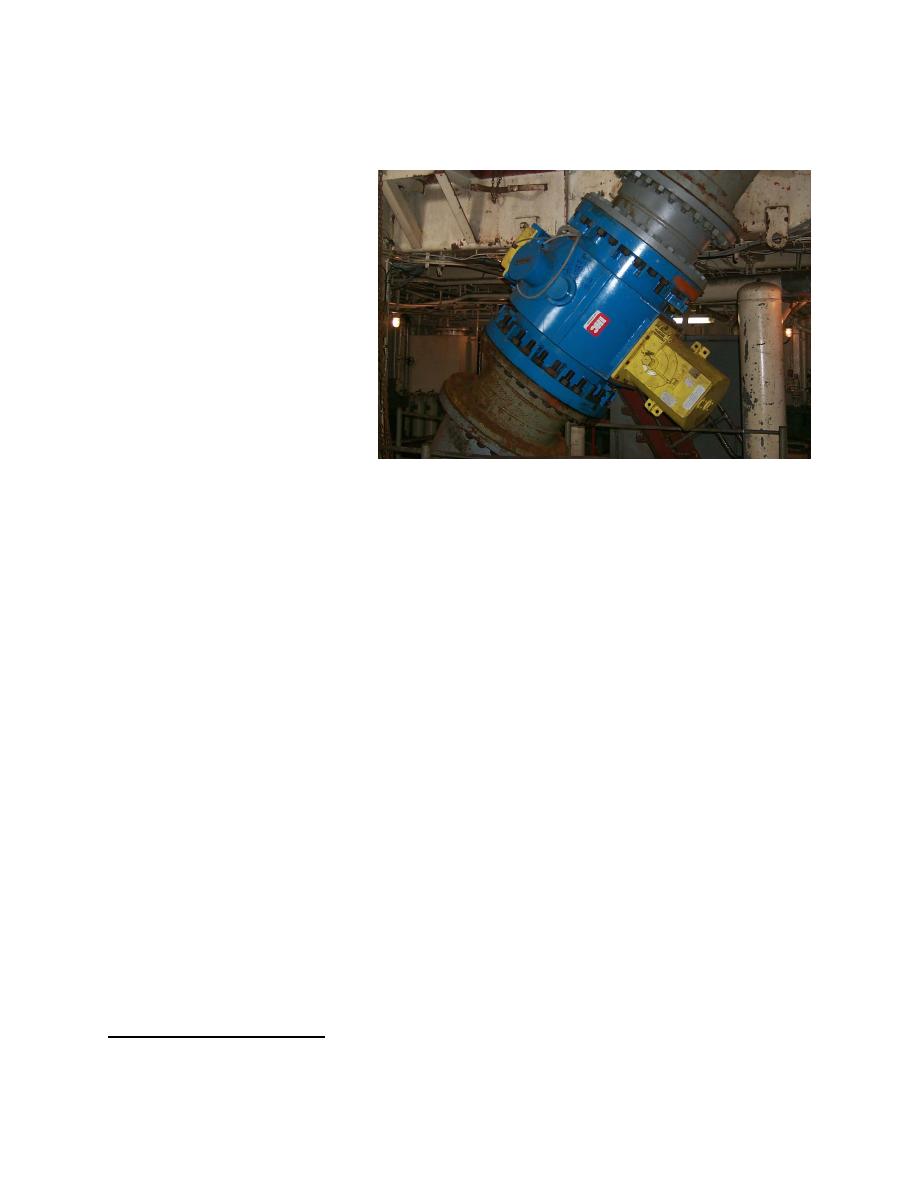

This production metering system

has a number of different output

indicators, but usually features a

display combining both slurry

velocity and slurry density. The

data from the flow meter (which

measures the total rate of slurry

flow), and the density meter

(which measures the specific

gravity of the pumped mixture)

are fed into the production

metering system. It indicates the

instantaneous total rate of solids

flow per unit time in a variety of

output parameters per unit time

i.e., cubic meters (or yards) per

hour, tons per hour, etc. It can also include a `totalizer,' which gives a continuous indication of

total production (project total or shift total), eliminating the need for post-operation computations

to determine the total production (Herbich et al. 1992). The capability to calculate instantaneous

and total quantities allows dredge production meter values to be used as an aid in optimizing

dredge operation and production (Pankow 1989). These capabilities allow it to be integrated into

an automated monitoring system i.e., the Silent Inspector (Rosati and Prickett 2001).

ERDC conducted laboratory studies (Pankow 1989) on production meter components. Several

density gauges and flow meters manufactured by different companies were evaluated for

accuracy and reliability in a closed test loop. Different grain-size materials, slurry

concentrations, and velocity regimes were utilized for the study. General conclusions from the

study were:

Doppler.

Readings among the density gauges and the control density meter were almost identical.

Readings among the magnetic flowmeters and the control flow meter were very similar.

Readings among the Doppler flowmeters and the control flowmeter were significantly

different.

The preferred pipe orientation for both density gauge and flowmeter is vertical, but a

horizontal pipe is acceptable by avoiding high slurry concentrations that produce a stationary

or sliding bed with dune formation. The difference between vertical and horizontal

orientation is on the order of 1 percent for the density gauge, 3 percent for the magnetic

flowmeters, and 5 percent for the Doppler flowmeters.

1

Accuracy is defined here as the agreement between a measurement and an accepted reference value that, when

applied to a set of measurements, involves a combination of random and systematic components.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |