|

||

|

|

||

|

Page Title:

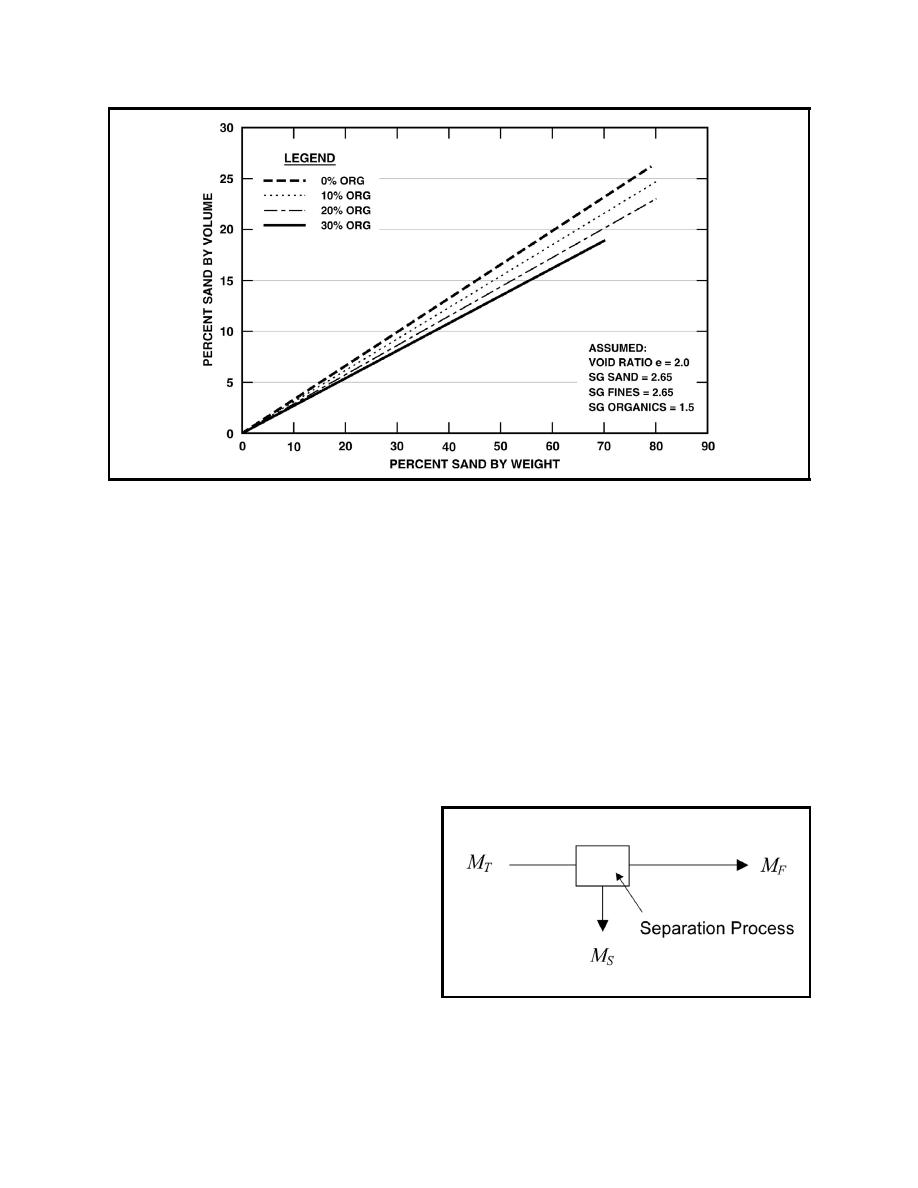

Figure 5. Percent sand by volume versus percent sand by weight, for void ratio 2.0 and organic specific gravity of 1.5 |

||

| |||||||||||||||

|

|

ERDC TN-DOER-C27

July 2002

Figure 5. Percent sand by volume versus percent sand by weight, for void ratio 2.0 and organic specific

gravity of 1.5

the entire deposit, coupled with proportional bulk sediment volumes, the best- and worst-case

volume reduction potential for the total project volume can be roughly estimated.

In the recovery of a specified fraction from the bulk material, the material is slurried and separated

around a "cut size" using equipment best suited to make the specified separation. Where a

coarse/fine separation is desired, the cut is typically made at about 75 m. The material does not

separate sharply at this cut size, however. A percentage of the material below the cut size will report

with the coarse material. Similarly, a percentage of the material above the cut size will report with

the fines. These proportions will vary depending upon the type and efficiency of the selected

process. The major products will typically include a coarse fraction, a fine fraction, and a wastewater

stream. These concepts are illustrated in Figures 6 and 7.

Solids Mass Balance - Although the sedi-

ment or dredged material will be slurried with

water in the course of dredging and process-

ing, conceptually it is helpful to look at the

solid and water balances separately. Figure 6

is a simplification of the actual distribution

of solids.

MT is the solids mass flow rate (M/T) from a

dredge or CDF excavation process, and is Figure 6. Solids mass balance diagram

represented by the following equation:

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |