|

||

|

|

||

|

Page Title:

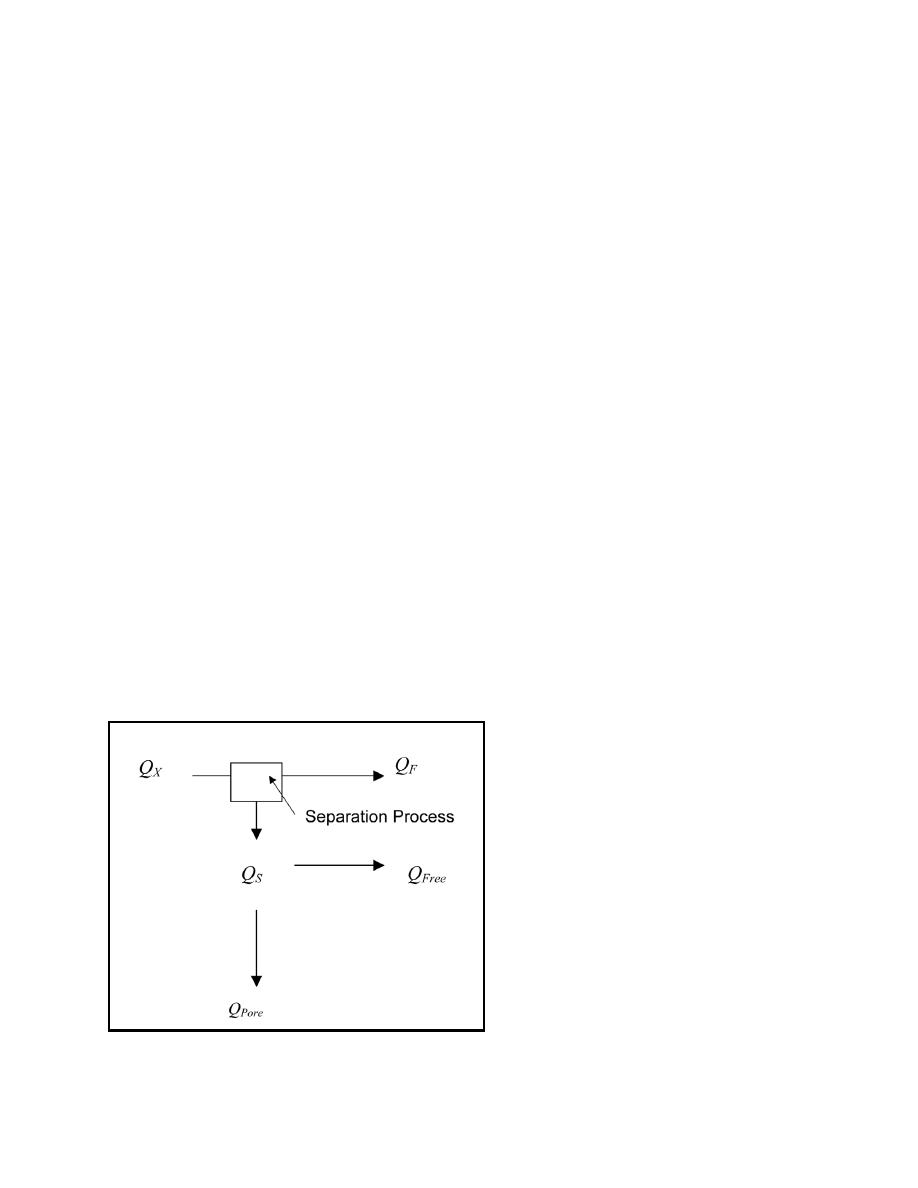

Figure 7. Water balance diagram |

||

| |||||||||||||||

|

|

ERDC TN-DOER-C27

July 2002

MT = Qsρs

(4)

where

Q = the volumetric flow rate to the separation process, V/T

s = percent solids by volume, as decimal, unitless

ρs = particle density, M/V

MS is the solids mass flow rate of the coarse material from the separation process, and is given by

MS = xmMTc

(5)

where

xm = efficiency of coarse solids separation on a mass basis, unitless (decimal)

c = percent coarse (specified cut size) by mass in bulk material, unitless (decimal)

MF is the solids mass flow rate of the fines from the separation process, and is given by the following,

assuming 100 percent of the fines reports with the process overflow. The first term represents the

coarse material that reports to the fine fraction as a result of process inefficiency:

MF = MTc (1 - xm) + MT (1 - c)

(6)

Volumetric Water Balance QX is the volumetric flow rate of water to the separation process

(Figure 7). QF is the flow rate reporting with the fines, typically the bulk of the processing water.

QS is the flow rate reporting with the coarse fraction. Some of this water will be free draining

(QFree), and will be captured and returned to the process or released as effluent. The residual pore

water makes up the remainder (QPore). QF

and QFree represent volumetric flows that

must be managed. Following a settling or

dewatering process to remove solids, they

may be recirculated through the process, or

treated and released as effluent. Process

slurries are typically fairly dilute, with 10 to

15 percent solids by volume being repre-

sentative. Process water volumes are there-

fore relatively high. Volumes reported in

the literature ranged from approximately

1,000 gallons to 1,700 gallons process water

per cubic yard processed and dewatered

sediment.

The coarse solids fraction is typically tar-

geted for beneficial use and the fine fraction

Figure 7. Water balance diagram

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |