|

||

|

|

||

|

Page Title:

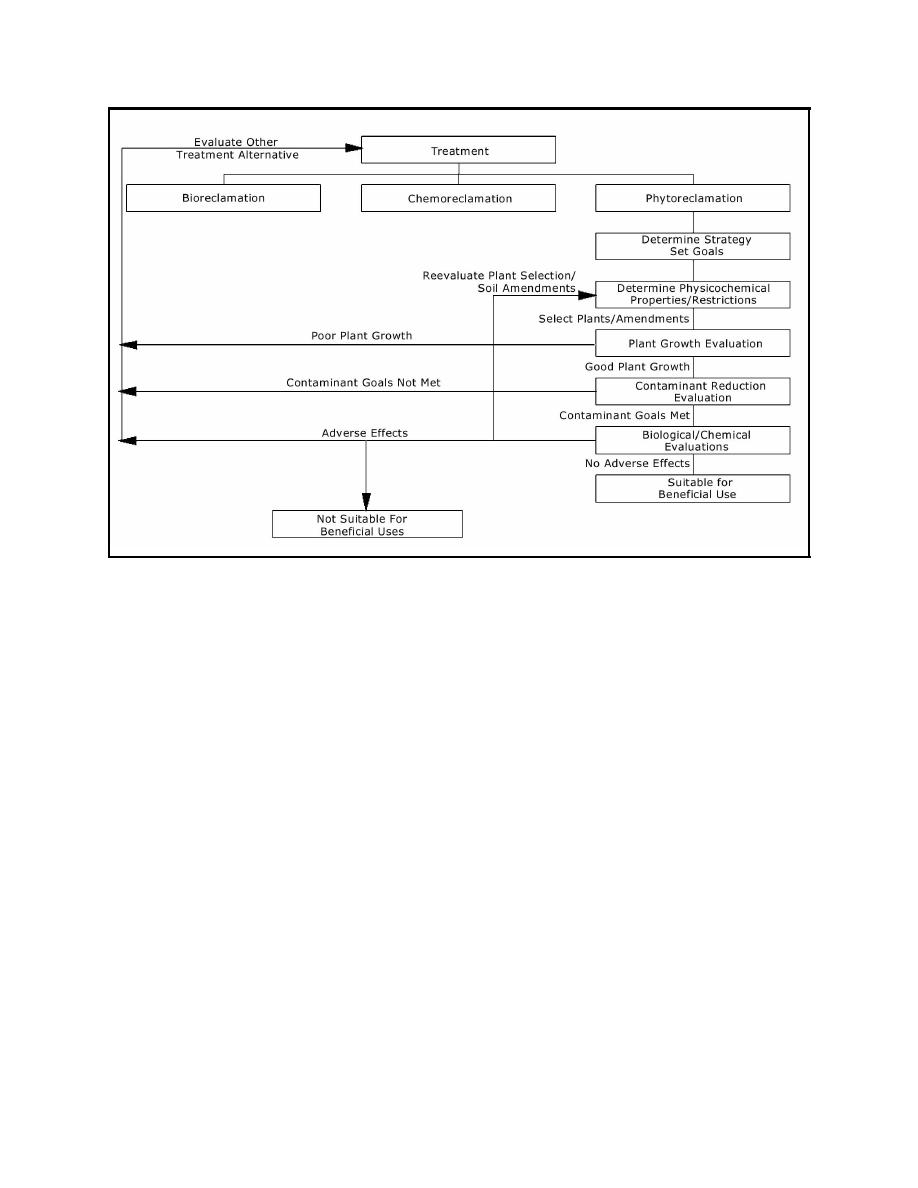

Figure 4. Schematic of the phytoreclamation framework |

||

| |||||||||||||||

|

|

Technical Note DOER-C3

May 1999

Figure 4. Schematic of the phytoreclamation framework

(1998a). These tests must be conducted on both fresh and aged material, as disturbance, aging, and

leaching of a dredged material will likely result in changes to some of the above parameters. There

are also chemical extraction tests available to predict uptake of and availability of metals to plants,

such as the diethylene triamine pentaacetic acid (DTPA) extraction procedure (Lee, Folsom, and

Bates 1983). The physical/chemical properties of some dredged materials may limit the use of

phytoreclamation. Excessive salt or contaminants, low or high pH, and other excessively high or

low soil parameters may inhibit plant growth. The following procedures are necessary to determine

potential for plant growth and survival on dredged material, and additional information is included

to assist in the selection of suitable plant species.

Aging and Oxidation of Dredged Material. In most cases, the application of phytore-

clamation will occur in an upland condition. The long-term effects of aging and drying of

dredged material removed from an aquatic or wetland, anaerobic condition and placed in an

upland, aerobic condition may include physical and chemical changes such as reduction in

pH and increases in availability of some metals. Changes in physical and chemical properties

have previously been predicted on both freshwater and saltwater dredged material (Environ-

mental Laboratory 1987; Lee et al. 1992a,b; 1993; Skogerboe et al. 1987; Skogerboe, Price,

and Brandon 1988). These long-term processes can be simulated very quickly in the

laboratory and should be performed prior to proceeding with the evaluation process. For

freshwater dredged material, the process simply requires air-drying and placing the material

in a controlled greenhouse environment for 3 weeks or until the moisture content is reduced

to less than 5 percent on an oven-dry weight basis. The material is then ground to pass a

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |