|

||

|

|

||

|

Page Title:

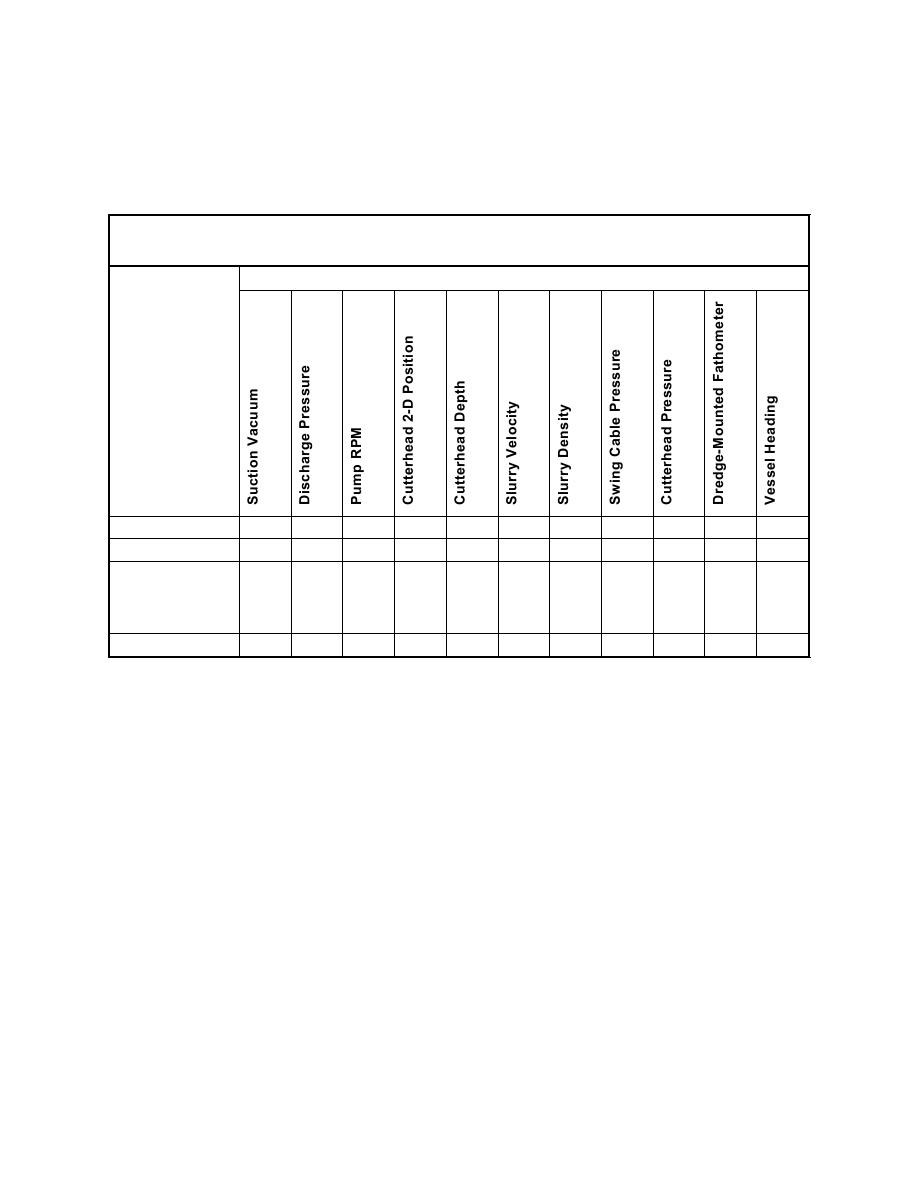

Table 1. Dredging Parameters Monitored by Districts |

||

| |||||||||||||||

|

|

Technical Note DOER-I1

July 1999 (Revised April 2000)

collect it. The following paragraphs describe the various types of information currently collected

by Corps Districts primarily for quality management (QM); i.e., to ensure end product quality as

per contract specifications and drawings. A summary of the dredging parameters monitored, by

District, is presented in Table 1.

Table 1

Dredging Parameters Monitored by Districts

Parameters

District

New Orleans

X

X

X

Louisville

X

X

X

X

X

X

X

X

X

X

Mobile

"Tuscaloosa"

X

X

X

X

X

X

"Columbus"

X

X

X

X

X

X

"Panama City"

X

X

X

X

X

X

San Francisco

X

X

X

When Alexis von Schmidt constructed the first practical suction pipeline dredge in 1876 (Huston

1986), its progress was probably ascertained by taking depth measurements with a sounding line or

pole in the dredge prism. Today, hydrographic surveys are still used by dredging Districts to assess

contract conformance (e.g., before-dredge surveys for reference, progress surveys, and after-dredge

surveys); but since that first pipeline dredge navigation job conducted over a hundred years ago,

there have been additional types of dredge-activity information collected for QM purposes.

New Orleans District: The suite of dredge parameters that has been measured and recorded for

the longest time (after hydrographic surveys) is the pump vacuum and pressure. The leverman uses

the instantaneous vacuum and pressure readings to assist in production optimization; but when the

time series values are recorded, they can be analyzed to identify intervals of dredge operation and

downtime. In the New Orleans District where rental contracts are used, the contractor is required

to record vacuum and discharge pressures on circular chart paper (smoke charts) like the one shown

in Figure 1. On dredges equipped with, and using, a ladder pump, the vacuum gauge and vacuum

chart are not required. The New Orleans District also requires the contractor to collect pump engine

revolutions per minute (rpm's) of the prime mover with a recording tachometer. On a daily basis,

the contractor delivers the completed recordings to the inspector on watch at the time of removal

from the recording device. All instrumentation must have a valid and current calibration certificate

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |