|

||

|

|

||

|

Page Title:

Figure 2. TDS sensor components |

||

| |||||||||||||||

|

|

ERDC TN-DOER-I2

July 2000

When the values of the specific density of the dry particles and density of the in situ water are known

from field surveys of the dredge site, then the mass of dry particles in the hopper with a load of

dredged material with a measured volume V, m3, can be calculated as follows:

TDS, or total mass of dry particles in hopper = (P)( ρs )(V)

b ga f

ρ - ρw

= h

ρs V

(4)

ρs - ρw

where TDS is given in tonnes dry solids (1 metric tonne equals 1,000 kg of mass).1

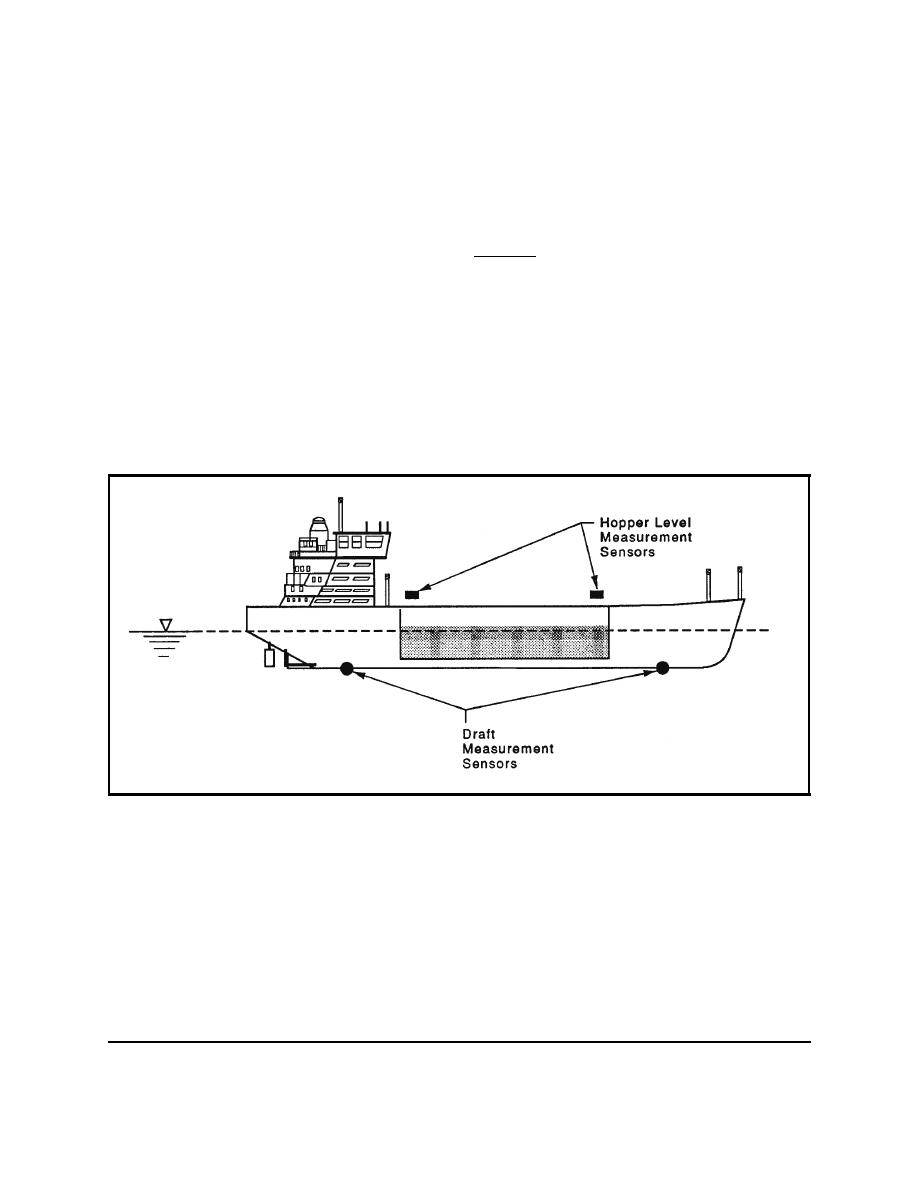

TDS Methodology. TDS involves the measurement of the volume and weight of the hopper load

to determine its average density and the quantity of dry solids that it contains. The level of dredged

material in the hopper is measured to derive the hopper load volume from the hopper ullage chart.

The hopper level can be measured by level sensors mounted over the hopper (Rokosch 1989) as

shown in Figure 2.

Figure 2. TDS sensor components

These hopper level sensors are usually ultrasonic transducers that emit acoustic waves and detect

the energy reflected from the dredged material surface. Similar to a hydrographic survey, the

distance between the transducer and the acoustic reflector is based on the time interval required for

the acoustic energy to travel from the transducer, bounce off the hopper material, and then return

to the transducer. The weight of the hopper load is determined by measuring the loaded and

unloaded weights of the vessel, then subtracting the unloaded value from the loaded value to

determine hopper weight. To accomplish this, the vessel change in draft is measured, and this

measurement is converted into displacement from the curves of hydrostatic properties of the

1

In Corps TDS measurement, the metric tonne (mass) unit is converted into the long ton (weight) unit, 2,240 lb.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |