|

||

|

|

||

|

Page Title:

Potential Nearshore Placement Benefits |

||

| |||||||||||||||

|

|

Technical Note DOER-N3

March 1998

maintenance dredging can, for illustration purposes, be separated into dredging and disposal costs,

the latter of which is the focus of this technical note. Much of the cost of disposal is a function of

time (e.g., time for a hopper dredge to transit to/from an offshore disposal site). The farther a hopper

dredge has to travel during the dredge cycle, the more fuel that is consumed, and the longer it takes

to dredge a project. Nearshore placement of mixed dredged material, in many cases, would reduce

transit times for hopper dredges and possibly reduce pumping distance for some pipeline dredges,

both of which would result in reduced costs.

In addition, nearshore placement has applications

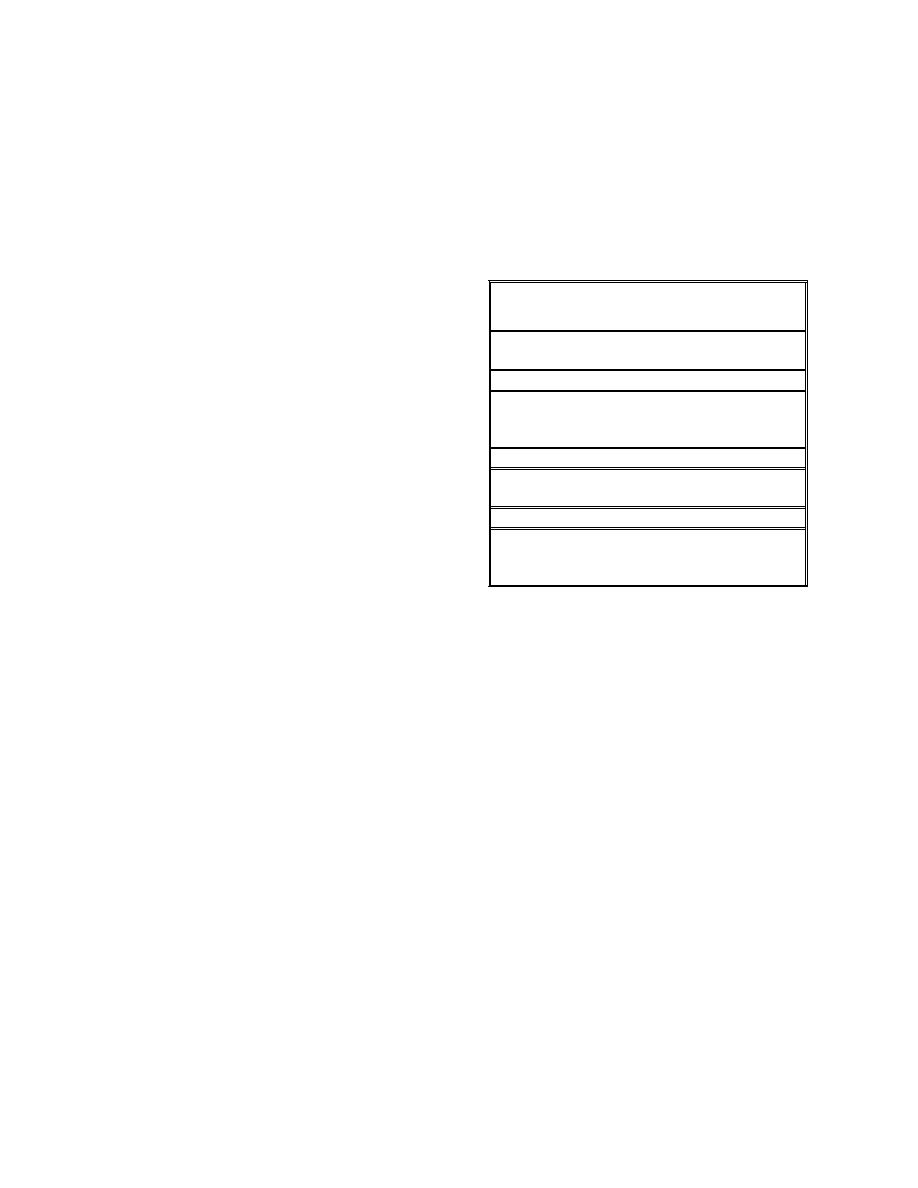

Potential Nearshore Placement

as a beneficial use approach, as material that tradi-

Benefits

tionally is placed offshore and lost to the local

Supplements beach profile by adding

littoral zone now would be kept nearby and possibly

material to the littoral zone

enhance nearshore profiles and/or beaches. Near-

Renourishes beach

shore placement could also offer a link between the

Decreases nearshore wave heights, thereby

often independent channel dredging activities and

reducing damage from erosive waves and

beneficial use (e.g., beach nourishment) activities.

storms

By linking these activities, interactive project de-

Provides fisheries habitat

sign is facilitated, and both navigation and beach

Reduces use of limited-capacity upland and

offshore disposal sites

use interests can collectively identify a least-cost

Decreases mobilization/demobilization costs

dredging and nearshore placement solution benefit-

Shortens haul distance for hopper dredges

ting all parties. Potential benefits from nearshore

and shorter pumping distance for pipeline

placement of mixed sediments are provided in the

dredges

adjacent table.

NEARSHORE PLACEMENT OBJECTIVE: Initially, planners and designers must decide on

the objective of the nearshore placement. Objectives of nearshore placement of dredged material

vary from simply placing the material in the littoral zone to "feed" the littoral system to designing

and constructing a nearshore berm feature that attenuates waves or serves as a habitat.

Commonly, nearshore placement involves design and construction of a nearshore berm or mound.

Typically, finer grained sediments (which are less desirable on beaches) placed with hopper dredges

or barges (from clamshell/bucket dredges) are used to construct "stable" berms in deeper water. If

the berm relief is sufficiently tall compared with the water depth and local wave climate, stable

berms can reduce wave energy on their lee. For "feeder" berms, material more closely resembling

native sands is used to match local beach sand and/or nearshore sand. Nearshore placement (in the

form of berms) can also serve as fish habitat. Design guidance of nearshore berms was developed

under the WES Dredging Research Program (DRP) and is provided in McLellan (1990a, b), Burke

and Allison (1992), and Pollock and Allison (1993). For illustration, an analytical study (using the

DRP guidance) was conducted to determine the economic feasibility of a nearshore berm

alternative for the St. Johns County, Florida, Beach Erosion Control Project. This effort is

described in Pollock, Curtis, and Moritz (in preparation).

In some cases, a designed "berm" may not be desired or cannot be constructed with available

material. However, nearshore placement may keep material in the local littoral zone to facilitate

marsh creation (or slow marsh degradation) or act sacrificially in lieu of nearby beaches or marshes.

2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |