|

||

|

|

||

| |||||||||||||||

|

|

ERDC TN-DOER-T7

October 2004

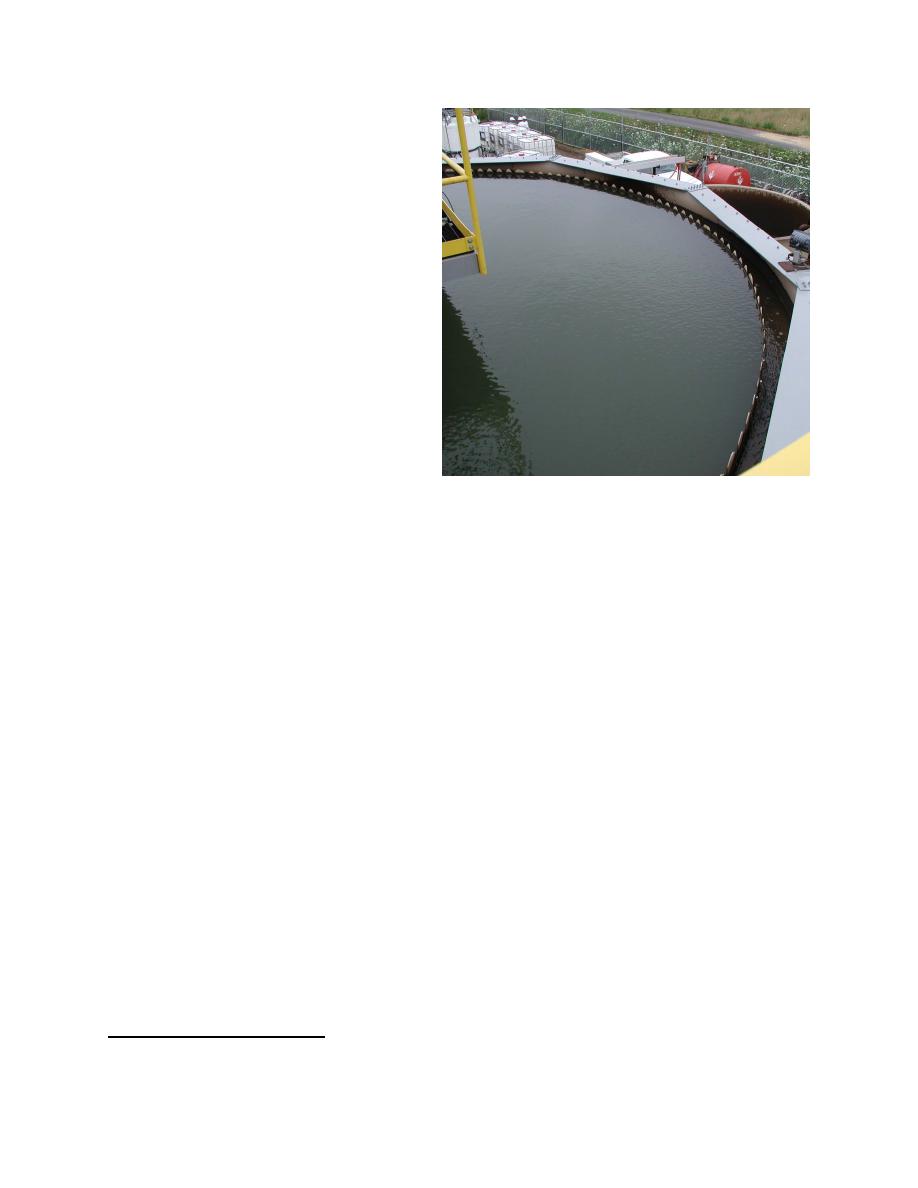

Clarifiers/Thickeners.

High rate,

circular

clarifiers/thickeners

are

appropriate for a wide variety of dredged

sediment slurries. Typically, suspended

solids are increased from 10 to 20 percent

dry solids in the influent, to approximately

30 percent solids in the underflow, greatly

reducing the slurry volume in the process

with this equipment. At the same time,

clarified water overflows a weir and is

available as process water or is returned to

the receiving water body (Figure 5).

Polymers are required to accelerate

sedimentation and optimize clarified water

quality. Features include the ability to

process a high volume of solids without

fouling, minimum space requirement,

rugged construction, and low SS in the

overflow (15-30 mg/l).

Figure 5. Circular clarifier

When used to thicken feed for a belt filter press, additional polymers may be added to the

underflow, or the solids may need some dilution to meet optimum feed concentrations to the

press. Solids can be continuously stirred to maintain pumpability during system shutdown, a

significant advantage over lamellar clarifiers. Lamellar, plate-type clarifiers are frequently used

for lower concentrations of suspended solids, emphasizing the need for clarification of the

overflow water, rather than for the thickening of the underflow. Polymers are required, and the

plates are sometimes subject to solids build-up and plugging, especially when applied to heavy

concentrations of sticky solids.

As a processing alternative, the clarifier may be used as the principal dewatering component.

Operated for maximum thickening, a circular clarifier can produce a pumpable underflow of up

to 40 percent solids. These partially dewatered materials can then be placed in a containment

area for further consolidation. Although a temporary dewatering area would be required, this

might be a more cost-effective alternative than mechanical dewatering. Clarifier capacity can be

increased at less cost than press capacity, enabling the use of larger dredges for which labor costs

are comparable to smaller dredges. Additionally, the dredge can operate more continuously if

the capacity of the rate limiting components is increased. This reduces the length of time the

Polymer Mixing and Injection Systems. Dry or liquid polymers (nonionic, anionic or

cationic) are available for thickening and/or dewatering dredged sediment slurries. To

economically justify more capital-intensive dry systems, the polymer requirements must be very

substantial because of the solids throughput in the system or because of the large size of the

processing system. Small, packaged systems blending neat polymer with water and then

1

Personal communication. May 13, 2004, Vic Buhr, Division Manager of Hydraulic Dredging and Dewatering, J.F.

Brennon Co., 820 Bain Bridge, LaCrosse, WI 54602-2557.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |