|

||

|

|

||

|

Page Title:

Dredged material capping versus in situ capping for remediation |

||

| |||||||||||||||

|

|

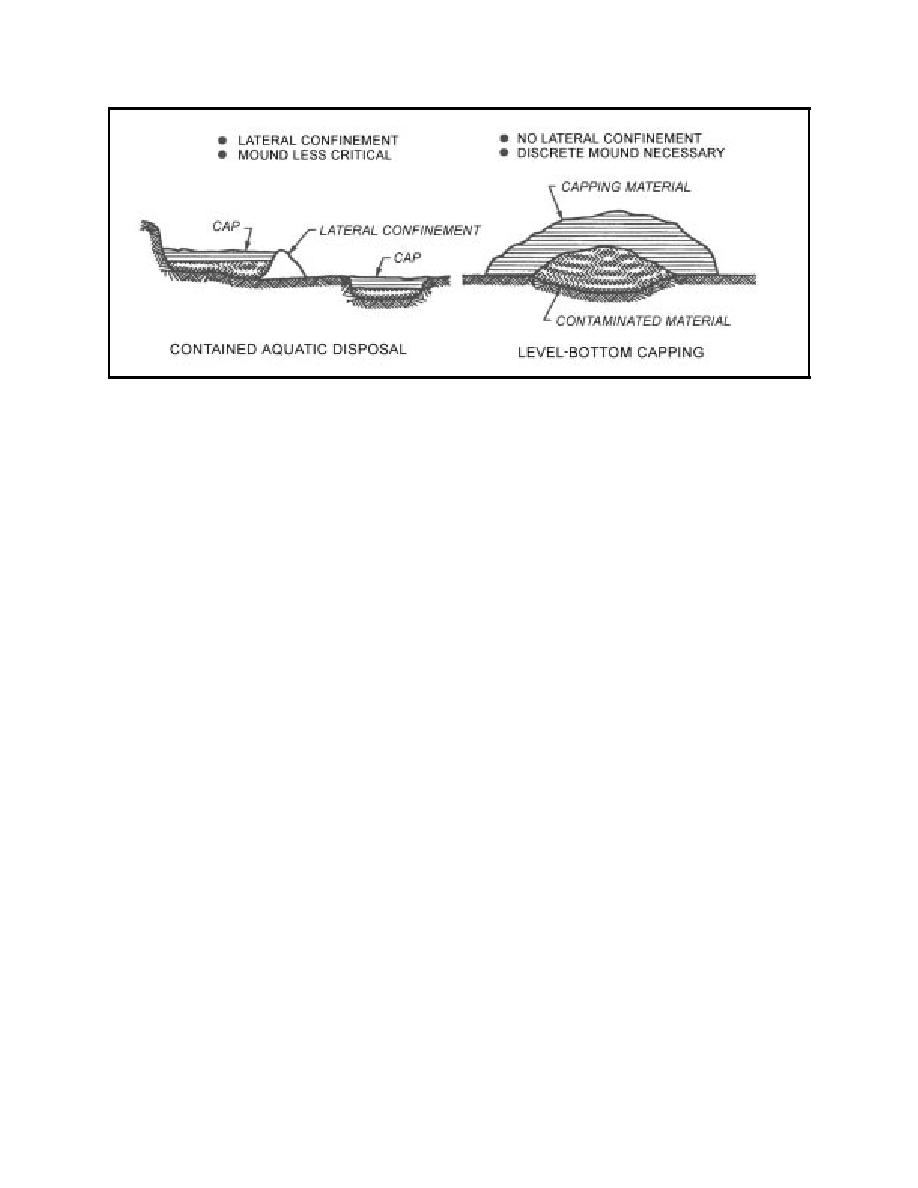

Figure 1.

Schematic illustrating LBC and CAD

where the mechanical properties of the contaminated material and/or bot-

tom conditions (e.g., slopes) require positive lateral control measures dur-

ing placement. Use of CAD can also reduce the required quantity of cap

material and thus the costs. Options might include the use of an existing

natural or excavated depression, preexcavation of a placement pit, or con-

struction of one or more submerged dikes for confinement (Truitt 1987a).

Dredged material capping versus

in situ capping for remediation

Capping is also a potential alternative for remediation of contaminated

sediments in place or in situ. However, a clear distinction should be made

between navigation dredged material capping and capping in the remedia-

tion context. For dredged material capping associated with navigation pro-

jects, the sediment of concern would typically require capping because it

may exhibit potential for toxicity or significant bioaccumulation in benthic

organisms. Often these sediments are only marginally contaminated in

comparison with other sediments in the area. The objective of capping in

this context is to effectively eliminate direct exposure of benthic organisms

to the contaminated sediments and thus virtually eliminate potential ben-

thic toxicity or bioaccumulation.

For in situ capping in the remediation context, the sediments of concern

are sufficiently contaminated to warrant some sort of cleanup action. The

objective of capping in the remediation context may involve objectives

over and above isolation of the sediment from the benthic environment.

Guidance for in situ capping for sediment remediation is presented in

Palermo et al. (1996).

Design issues for capping

Capping is a contaminant control measure to prevent impacts. However,

dredged material capping requires initial placement of a contaminated

4

Chapter 1 Introduction

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |