|

||

|

|

||

| |||||||||||||||

|

|

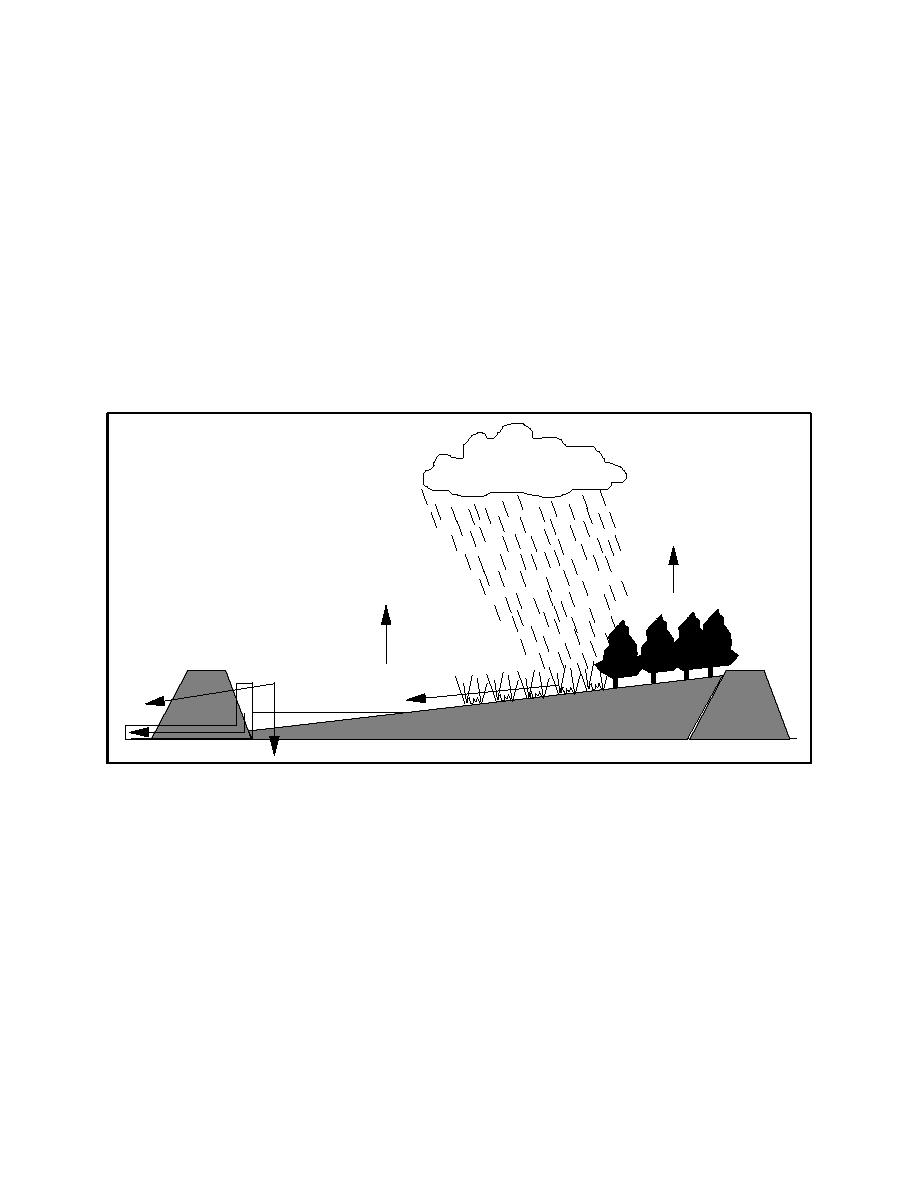

5.1.1 Runoff Processes

The runoff pathway is of potential concern as soon as the water ponded

during placement is decanted and the dredged material is exposed to precipitation

and continues as long as the dredged material surface is exposed through the life

of the CDF. A schematic of CDF conditions and fate of runoff water in a CDF is

shown in Figure 5-1. Immediately after disposal and initial decanting processes,

resuspension of newly placed dredged material through the process of

precipitation impact on the dredged material surface will generate runoff water

similar to effluent water produced during filling. Suspended solids in the runoff

can range up to 10 g/L during this stage, and most contaminants will be associated

with these suspended solids. Most heavy metals will be low in the dissolved

phase and high nutrient levels associated with anaerobic conditions in the dredged

material will still be present. If CDF weirs are boarded such that they provide

retention of runoff prior to discharge, TSS in runoff will be reduced.

Transpiration

Runoff

Leaching

Ponded

Discharge

Figure 5-1. Illustration of the CDF surface runoff process

Once the dredged material surface is exposed, the material begins to dry and

oxidize. Runoff quality from dried and oxidized dredged material may differ

significantly from the effluent water quality during dredged material disposal. For

instance, some metals become very soluble once dredged material oxidizes, and

simply controlling suspended solids discharges in runoff will not control the

discharge of metals in runoff released from the CDF. Since effects on runoff

quality, such as ponding and runoff rates, are variable because of site management

and climatic conditions, the runoff evaluation presently only considers direct,

uncontrolled discharge in the testing process.

5-2

Chapter 5

Surface Runoff After Disposal Operations

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us - Support Integrated Publishing |